Global Automotive Oe Bumper Cover Market

Market Size in USD Billion

CAGR :

%

USD

45.41 Billion

USD

110.84 Billion

2025

2033

USD

45.41 Billion

USD

110.84 Billion

2025

2033

| 2026 –2033 | |

| USD 45.41 Billion | |

| USD 110.84 Billion | |

|

|

|

|

Automotive OE Bumper Cover Market Size

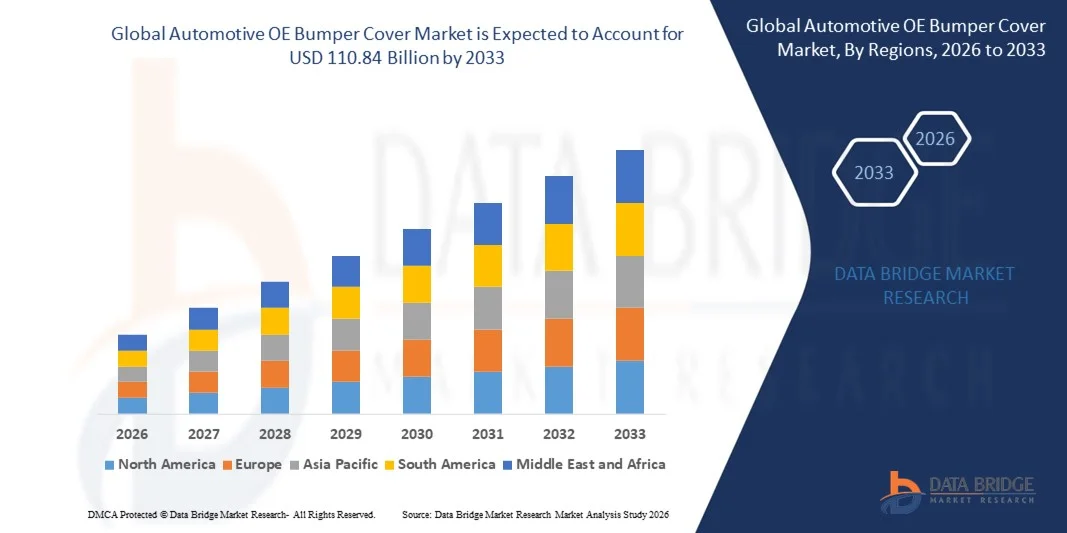

- The global automotive OE bumper cover market size was valued at USD 45.41 billion in 2025 and is expected to reach USD 110.84 billion by 2033, at a CAGR of 11.80% during the forecast period

- The market growth is largely fueled by the increasing production of vehicles and the rising focus on vehicle safety, aesthetics, and lightweight design, which drive demand for advanced bumper cover solutions

- Furthermore, growing adoption of electric and hybrid vehicles is encouraging OEMs to integrate innovative, durable, and aerodynamic bumper covers. For instance, Plastic Omnium (France) is developing lightweight polymer-based bumpers to enhance efficiency and safety, boosting market expansion

Automotive OE Bumper Cover Market Analysis

- Automotive OE bumper covers are exterior components designed to absorb impact, protect vehicle structures, and improve aerodynamic performance. They are manufactured using materials such as polypropylene, thermoplastic olefins, and composites, offering both functional and aesthetic benefits

- The rising demand for OE bumper covers is primarily driven by stricter vehicle safety regulations, increasing consumer preference for stylish and durable components, and the need for lightweight materials to improve fuel efficiency and EV performance

- Asia-Pacific dominated the automotive OE bumper cover market with a share of around 48% in 2025, due to rapid automotive production, expanding passenger vehicle sales, and strong presence of OEM manufacturing hubs

- North America is expected to be the fastest growing region in the automotive OE bumper cover market during the forecast period due to increasing vehicle production, rising demand for lightweight and durable bumper covers, and adoption of advanced manufacturing processes

- Thermoplastic segment dominated the market with a market share of 52.5% in 2025, due to its lightweight nature, flexibility, and high impact resistance. Thermoplastic bumper covers are easier to manufacture at scale and can be painted to match vehicle exteriors seamlessly, making them highly suitable for passenger vehicles. The segment also benefits from recyclability and lower production costs, which align with the automotive industry’s sustainability goals. OEMs prefer thermoplastic materials for their ability to absorb minor impacts without structural damage, further enhancing their market dominance

Report Scope and Automotive OE Bumper Cover Market Segmentation

|

Attributes |

Automotive OE Bumper Cover Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Automotive OE Bumper Cover Market Trends

Rising Adoption of Lightweight and Aerodynamic Bumper Covers

- A significant trend in the automotive OE bumper cover market is the increasing adoption of lightweight and aerodynamically optimized bumper covers, driven by the demand for improved fuel efficiency, reduced emissions, and enhanced vehicle aesthetics. These bumper covers are being engineered to combine impact resistance with weight reduction, positioning them as critical components in modern vehicle design

- For instance, companies such as Magna International and Faurecia are supplying advanced thermoplastic bumper covers that meet stringent OEM specifications while reducing vehicle weight. Such solutions contribute to better performance, fuel efficiency, and regulatory compliance across passenger and commercial vehicles

- The trend toward integrating multifunctional bumper covers is rising as designs now incorporate sensors, cameras, and radar modules to support ADAS (Advanced Driver Assistance Systems). This is enabling bumper covers to play an active role in safety, collision detection, and autonomous driving capabilities

- The growing emphasis on vehicle aesthetics and customization is pushing manufacturers to adopt sleek, aerodynamic bumper cover designs that improve overall vehicle styling. Consumers are increasingly expecting visually appealing exteriors without compromising durability or safety performance

- Automotive OEMs are increasingly deploying composite materials and high-strength plastics for bumper covers to balance structural integrity with weight savings. This adoption is helping manufacturers meet evolving safety standards while maintaining cost efficiency in production

- The market is witnessing stronger integration of bumper covers with overall vehicle body design to optimize airflow, reduce drag, and enhance energy efficiency. This focus on performance, safety, and design is positioning advanced bumper covers as essential elements in modern automotive engineering

Automotive OE Bumper Cover Market Dynamics

Driver

Growing Focus on Vehicle Safety and Regulatory Compliance

- Rising regulatory requirements for vehicle safety, including pedestrian protection and crashworthiness, are driving OEMs to prioritize high-performance bumper covers. These regulations are compelling manufacturers to design bumpers that absorb impact effectively and reduce injury risks in collisions

- For instance, companies such as Honda and BMW are implementing bumper systems that comply with Euro NCAP and U.S. NHTSA safety standards. Such compliant designs enhance vehicle safety ratings and build consumer trust while meeting stringent regional regulations

- The increasing adoption of advanced driver assistance systems (ADAS) requires bumper covers to integrate sensors, cameras, and radar modules without compromising structural integrity. This is positioning bumper covers as multifunctional components essential for modern automotive safety technologies

- Automakers are emphasizing the use of high-strength and impact-absorbing materials in bumper covers to improve overall crash performance. This material innovation supports both passenger safety and compliance with evolving global safety norms

- The market is witnessing stronger collaboration between OEMs and material suppliers to develop cost-effective, durable, and regulation-compliant bumper covers. This synergy is reinforcing the role of bumper covers as key enablers of vehicle safety and innovation

Restraint/Challenge

High Production Costs and Material Volatility

- The automotive OE bumper cover market faces challenges from high production costs and the volatility of raw materials such as thermoplastics and composites, which affect pricing and supply stability. These factors create complexity in balancing cost efficiency with performance and safety requirements

- For instance, companies such as Continental and Plastic Omnium experience fluctuations in polymer and composite material prices, impacting production planning and profitability. Such cost pressures necessitate strategic sourcing and process optimization across the supply chain

- Manufacturing lightweight, impact-resistant bumper covers requires sophisticated molding techniques and quality control, increasing operational expenditures. These technical requirements extend production timelines and limit flexibility in scaling output efficiently

- The reliance on specialized polymers and composites exposes manufacturers to supply chain risks, particularly during periods of raw material scarcity or global price volatility. This challenge impacts production consistency and overall market growth

- The market continues to navigate the need for balancing high-quality, compliant bumper covers with economic feasibility for OEMs. Managing production costs and material volatility remains a critical constraint for sustained expansion in the automotive OE bumper cover segment

Automotive OE Bumper Cover Market Scope

The market is segmented on the basis of design type, material type, process type, and vehicle type.

- By Design Type

On the basis of design type, the automotive OE bumper cover market is segmented into standard, deep down, and roll pan. The standard bumper cover segment dominated the largest market revenue share in 2025, driven by its widespread adoption in passenger vehicles and compatibility with various vehicle models. Manufacturers prefer standard designs for their cost-effectiveness, ease of integration, and ability to meet basic impact absorption requirements. The segment also benefits from established production techniques and strong demand from OEMs for replacement and aftermarket parts. Standard bumper covers provide consistent performance in safety tests and are often preferred for fleet vehicles, further reinforcing their market leadership.

The deep down design type is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by increasing adoption in SUVs, trucks, and premium vehicle segments. For instance, companies such as Magna International have reported rising demand for deep down bumpers due to their enhanced styling, improved aerodynamics, and better pedestrian safety performance. These designs also allow OEMs to integrate advanced sensors and parking assist systems more efficiently, driving adoption across modern vehicles. Consumer preference for vehicles with sporty aesthetics further supports the expansion of this segment.

- By Material Type

On the basis of material type, the market is segmented into thermoplastic, thermoset, and metal bumper covers. The thermoplastic segment dominated the largest market revenue share of 52.5% in 2025 due to its lightweight nature, flexibility, and high impact resistance. Thermoplastic bumper covers are easier to manufacture at scale and can be painted to match vehicle exteriors seamlessly, making them highly suitable for passenger vehicles. The segment also benefits from recyclability and lower production costs, which align with the automotive industry’s sustainability goals. OEMs prefer thermoplastic materials for their ability to absorb minor impacts without structural damage, further enhancing their market dominance.

The thermoset material segment is expected to witness the fastest growth rate from 2026 to 2033, driven by rising adoption in commercial vehicles and heavy-duty applications. For instance, BASF has emphasized the use of thermoset composites for enhanced durability, high-temperature resistance, and structural reinforcement in trucks and SUVs. These materials allow manufacturers to meet stringent safety regulations and deliver long-lasting performance under harsh conditions. Increasing investment in research and development of high-strength thermoset composites supports the rapid growth of this segment.

- By Process Type

On the basis of process type, the market is segmented into injection molding, reaction injection molding (RIM), vacuum forming, and others. The injection molding segment dominated the largest market revenue share in 2025, driven by its precision, repeatability, and cost-effectiveness for high-volume production. OEMs prefer injection molding for its ability to produce complex bumper shapes with consistent quality and surface finish. The process also allows integration of reinforcement materials and supports lightweight designs that improve vehicle fuel efficiency. Strong adoption across passenger vehicles and replacement parts manufacturing reinforces the dominance of this process type.

The reaction injection molding (RIM) segment is anticipated to witness the fastest growth rate from 2026 to 2033 due to increasing demand for high-strength and lightweight bumpers in SUVs and commercial vehicles. For instance, Covestro has reported growing utilization of RIM processes for polyurethane-based bumpers that offer superior impact absorption and design flexibility. This process enables the production of thicker, more durable bumper covers without adding excessive weight, meeting both safety and performance requirements. Expansion of premium and off-road vehicle production supports the rapid growth of RIM.

- By Vehicle Type

On the basis of vehicle type, the market is segmented into passenger vehicles and commercial vehicles. The passenger vehicle segment dominated the largest market revenue share in 2025, driven by the extensive production of cars, SUVs, and crossovers worldwide. High consumer demand for aesthetics, safety, and customization options in passenger vehicles fuels the adoption of advanced bumper covers. OEMs prioritize bumper designs that combine impact resistance, lightweight performance, and seamless integration with sensors and cameras for ADAS systems. Replacement demand in the aftermarket also reinforces the revenue share of passenger vehicle bumper covers.

The commercial vehicle segment is expected to witness the fastest growth rate from 2026 to 2033, fueled by increasing logistics, transport, and fleet expansion activities. For instance, Denso has highlighted the growing adoption of reinforced bumper covers for trucks and buses to improve durability, safety, and regulatory compliance. Rising investment in commercial vehicle manufacturing and replacement demand in emerging markets further drives this segment. The focus on long-life performance and reduced maintenance costs supports the rapid expansion of bumper covers in this category.

Automotive OE Bumper Cover Market Regional Analysis

- Asia-Pacific dominated the automotive OE bumper cover market with the largest revenue share of around 48% in 2025, driven by rapid automotive production, expanding passenger vehicle sales, and strong presence of OEM manufacturing hubs

- The region’s cost-effective production landscape, growing automotive component exports, and rising adoption of lightweight materials are accelerating market expansion

- Availability of skilled labor, favorable government incentives, and rapid industrialization across developing economies are contributing to increased adoption of advanced bumper cover designs and materials

China Automotive OE Bumper Cover Market Insight

China held the largest share in the Asia-Pacific automotive OE bumper cover market in 2025, owing to its position as the world’s largest automotive manufacturer and strong OEM ecosystem. The country’s extensive production capacity, government support for automotive components, and growing exports of vehicles and spare parts are key growth drivers. Demand is also boosted by investments in lightweight thermoplastic materials, advanced manufacturing processes, and adoption of deep down and roll pan designs in modern vehicles.

India Automotive OE Bumper Cover Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by rising passenger vehicle production, expanding commercial vehicle fleets, and increasing investments in automotive component manufacturing. Initiatives such as “Make in India” and growing domestic R&D for lightweight and durable bumper covers are strengthening market growth. In addition, rising demand for thermoplastic materials, adoption of advanced injection and reaction injection molding processes, and modernization of automotive assembly plants are supporting rapid expansion.

Europe Automotive OE Bumper Cover Market Insight

The Europe automotive OE bumper cover market is expanding steadily, supported by stringent vehicle safety regulations, high demand for premium vehicles, and growing adoption of lightweight, impact-resistant materials. The region places strong emphasis on environmental compliance, material sustainability, and high-quality production standards. Increasing integration of advanced designs such as deep down and roll pan bumpers in passenger and commercial vehicles is further enhancing market growth.

Germany Automotive OE Bumper Cover Market Insight

Germany’s market is driven by its leadership in premium vehicle production, robust automotive supply chain, and export-oriented manufacturing model. The country has well-established R&D networks and collaborations between OEMs and component suppliers, fostering innovation in bumper cover materials and processes. Demand is particularly strong for thermoplastic and thermoset materials, as well as advanced injection molding and RIM processes for high-performance bumper covers.

U.K. Automotive OE Bumper Cover Market Insight

The U.K. market is supported by a mature automotive industry, focus on lightweight vehicle components, and adoption of advanced bumper designs for both passenger and commercial vehicles. Efforts to enhance local automotive supply chains post-Brexit and growing investments in sustainable thermoplastic and thermoset materials are strengthening market presence. The country continues to emphasize R&D collaborations, advanced manufacturing techniques, and high-quality material standards for OE bumper cover production.

North America Automotive OE Bumper Cover Market Insight

North America is projected to grow at the fastest CAGR from 2026 to 2033, driven by increasing vehicle production, rising demand for lightweight and durable bumper covers, and adoption of advanced manufacturing processes. Strong focus on vehicle safety, environmental regulations, and integration of sensors and ADAS technologies are boosting demand. In addition, reshoring of automotive component production and increasing collaboration between OEMs and suppliers are supporting market expansion.

U.S. Automotive OE Bumper Cover Market Insight

The U.S. accounted for the largest share in the North America market in 2025, underpinned by its expansive automotive industry, advanced R&D infrastructure, and strong OEM and supplier network. The country’s emphasis on lightweight materials, injection and reaction injection molding processes, and integration of innovative bumper designs in passenger and commercial vehicles is encouraging adoption. Presence of key automotive manufacturers and a mature distribution and aftermarket network further solidify the U.S.’s leading position in the region.

Automotive OE Bumper Cover Market Share

The automotive OE bumper cover industry is primarily led by well-established companies, including:

- Plastic Omnium (France)

- Motherson (India)

- Magna International Inc. (Canada)

- TONG YANG GROUP (South Korea)

- NTF GROUP (Italy)

- TOYOTA BOSHOKU CORPORATION (Japan)

- SEOYON E-HWA Automotive Slovakia (Slovakia)

- TOYODA GOSEI Co., Ltd. (Japan)

- Montaplast GmbH (Germany)

- Marelli Holdings Co., Ltd. (Italy)

- LG HAUSYS (South Korea)

- FLEX-N-GATE CORPORATION (U.S.)

- Volkswagen (Germany)

- Lucid (U.S.)

- MAZDA NORTH AMERICAN OPERATIONS (U.S.)

- BMW AG (Germany)

- Tesla (U.S.)

- Nissan (Japan)

Latest Developments in Global Automotive OE Bumper Cover Market

- In January 2024, Toyoda Gosei Co. Ltd. announced plans to invest USD 59.9 million to expand production capacity at TG Missouri Corporation (TGMO) and TG Kentucky, LLC (TGKY), two of its U.S. subsidiaries. This expansion is aimed at meeting the growing demand for interior and exterior automotive parts in North America. The increased production capability is expected to strengthen the company’s supply chain, enhance market responsiveness, and support higher adoption of advanced bumper covers across passenger and commercial vehicles in the region

- In September 2022, Sumitomo Chemical announced plans to open a new pilot-scale mechanical waste processing facility to develop a material recycling business using waste plastics collected from end-of-life automobiles. This initiative supports sustainable and circular manufacturing practices in the automotive sector. By enabling the reuse of thermoplastic and composite materials, the development is likely to reduce production costs, promote eco-friendly bumper covers, and enhance the adoption of recyclable components in OEM applications

- In April 2022, Novitec released a carbon fiber package for the Ferrari 458 Speciale, including a trunk-lid side panel set, front spoiler lip, taillight covers, air-intake louvre side window, double-fins, and flaps for the front air guide. This launch highlights the increasing demand for lightweight, high-performance materials in premium automotive segments. The introduction of carbon fiber bumper components demonstrates growing market focus on advanced materials that improve vehicle aesthetics, reduce weight, and enhance fuel efficiency

- In January 2021, an MoU was signed between Samvardhana Motherson Automotive Systems Group BV (SMRPBV) and Marelli Automotive Lighting to explore potential collaborations in smart illuminated external body elements, such as front grilles and bumpers, along with other illuminated automotive parts. This collaboration is expected to accelerate innovation in integrated exterior components, encouraging OEMs to adopt advanced bumper designs with functional lighting and sensor integration, which enhances both vehicle safety and market differentiation

- In March 2020, Magna International announced an expansion of its exterior components production line in Europe, aimed at increasing output of bumper covers for passenger vehicles and light commercial vehicles. This expansion is expected to strengthen the company’s position in the European OE market, improve lead times for OEMs, and support the adoption of advanced designs such as deep down and roll pan bumpers, reinforcing growth in lightweight and high-performance bumper cover segments

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.