Market Analysis and Insights : Global Additive Manufacturing with Metal Powders Market

Market Analysis and Insights : Global Additive Manufacturing with Metal Powders Market

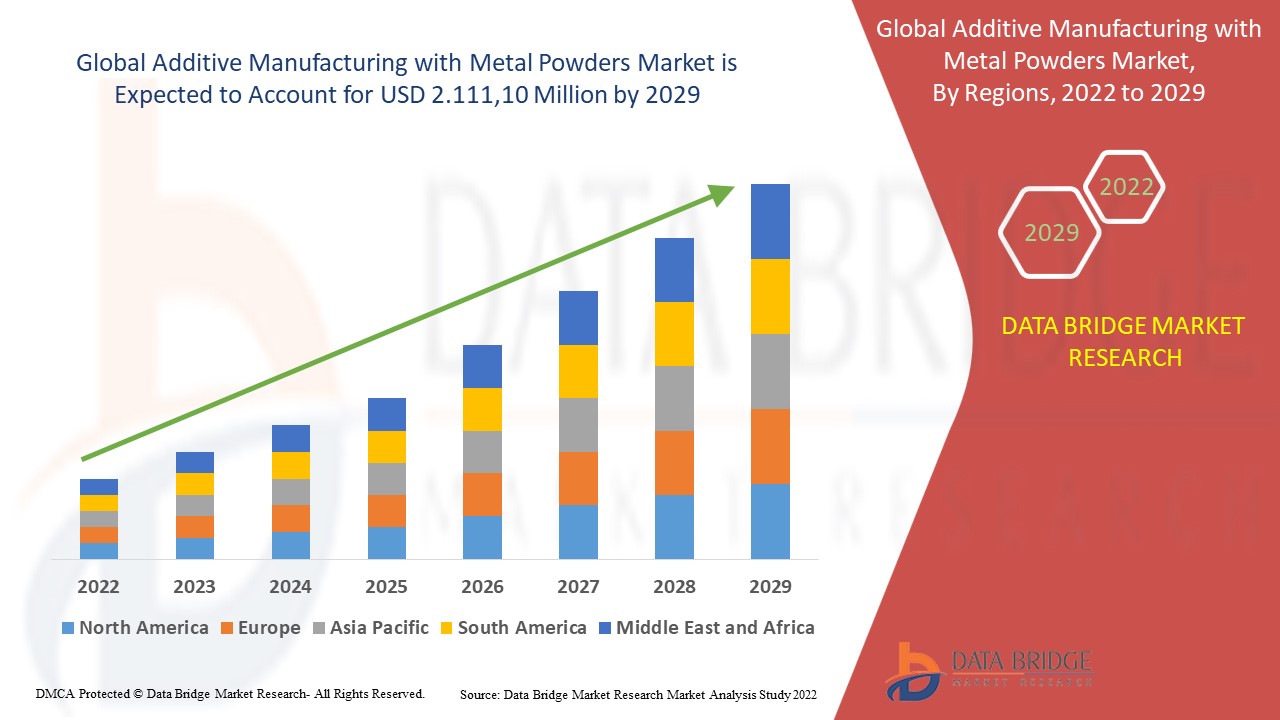

Data Bridge Market Research analyses that the additive manufacturing with metal powders market will witness a CAGR of 22.1% for the forecast period of 2022-2029 and is likely to reach at USD 2.111,10 million by 2029.

Additive manufacturing refers to associate industrial variant of 3D printing technology that manufactures 3D objects through 3D modeling package, machine instrumentality, and layering material. Additive producing with metal powders combines parts to fabricate objects from the 3D modeling information, usually layer-upon-layer. The technique is presently wide applied to supply dental restorations, medical implants, vehicles, aerospace, and different product.

The development of economies plays an essential role is the major factor accelerating the growth of the market. Furthermore, reduced manufacturing time, cost efficiency, high volume capability, less wastage are also expected to drive the growth of the additive manufacturing with metal powders market. However, high manufacturing cost restrains the additive manufacturing with metal powders market, whereas, technological limitation, and intellectual property issues will challenge market growth.

In addition, surging need from customers and surging demand from the global aerospace and defense and automobile industries will create ample opportunities for the additive manufacturing with metal powders market.

This additive manufacturing with metal powders market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on additive manufacturing with metal powders market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Global Additive Manufacturing with Metal Powders Market Scope and Market Size

The additive manufacturing with metal powders market is segmented on the basis of metal form, production method, companion technique and metal powder. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

- On the basis of metal form, the metal powder market is segmented into scrap/recycled metal, and ores.

- On the basis of production method, the metal powder market is segmented into physical, chemical, and mechanical.

- On the basis of compaction technique, market is segmented into cold compaction, and hot compaction.

- On the basis of metal powder, the metal powder market is segmented into ferrous metal powder and non-ferrous metal powder.

- Metal Form (Scrap/Recycled Metal, Ores), Production Method (Physical, Chemical, Mechanical), Compaction Technique (Cold Compaction, Hot Compaction), Metal Powder (Ferrous Metal Powder, Non-Ferrous Metal Powder),

Additive Manufacturing with Metal Powders Market Country Level Analysis

The additive manufacturing with metal powders market is analysed and market size, volume information is provided by country, metal form, production method, companion technique and metal powder referenced above.

The countries covered in the additive manufacturing with metal powders market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the additive manufacturing with metal powders market and will continue to flourish its dominance during the forecast period due to the metal powder customer, where increasing production of automotive components. However, Asia-Pacific will continue to project the highest CAGR for this period because of the lawn and garden, industrial, off-road, and agriculture.

The country section of the additive manufacturing with metal powders market report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Additive Manufacturing with Metal Powders Market Share Analysis

The additive manufacturing with metal powders market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to additive manufacturing with metal powders market.

Some of the major players operating in the additive manufacturing with metal powders market report are Allegheny Technologies Incorporated, American Axle & Manufacturing, Inc., American Chemet Corp., AMETEK Specialty Metal Products, Burgess-Norton Manufacturing Company, Carpenter Technology Corporation, Daido Steel Co, Ltd., Diamet Corporation, Dowa Holdings Co., Ltd., Erasteel SAS, F. W. Winter Inc. & Co., Federal-Mogul Holdings Corp., Fine Sinter Co., Ltd., GKN Sinter Metals, Inc., Hoeganaes Corp., H.C. Starck GmbH, Hitachi Chemical Company, Ltd., Hgans AB, JFE Steel Corp., Kennametal, Inc., Kobe Steel, Ltd., Kymera International, Miba AG, Norilsk Nickel, PMG Holding GmbH, Rio Tinto Metal Powders among other.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Additive Manufacturing With Metal Powders Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Additive Manufacturing With Metal Powders Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Additive Manufacturing With Metal Powders Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.