Global Additive Manufacturing Market

Market Size in USD Billion

CAGR :

%

USD

91.84 Billion

USD

419.22 Billion

2024

2032

USD

91.84 Billion

USD

419.22 Billion

2024

2032

| 2025 –2032 | |

| USD 91.84 Billion | |

| USD 419.22 Billion | |

|

|

|

|

Additive Manufacturing Market Analysis

The additive manufacturing market is experiencing rapid growth due to technological advancements. Enhanced 3D printing capabilities improve production efficiency and design flexibility across industries. Sectors such as aerospace, healthcare, and automotive increasingly adopt additive manufacturing for prototyping. The demand for lightweight and customized components further accelerates market expansion globally. Continuous material innovations, including metal and biocompatible polymers, expand application possibilities. Companies invest heavily in research to enhance precision and scalability in manufacturing. Improved cost-effectiveness and reduced material waste drive greater adoption across various industries. Rising automation in production processes further strengthens the integration of additive manufacturing technologies. Increased focus on sustainability encourages the shift toward efficient and resource-saving manufacturing methods. As industry adoption rises, additive manufacturing continues to transform modern production landscapes.

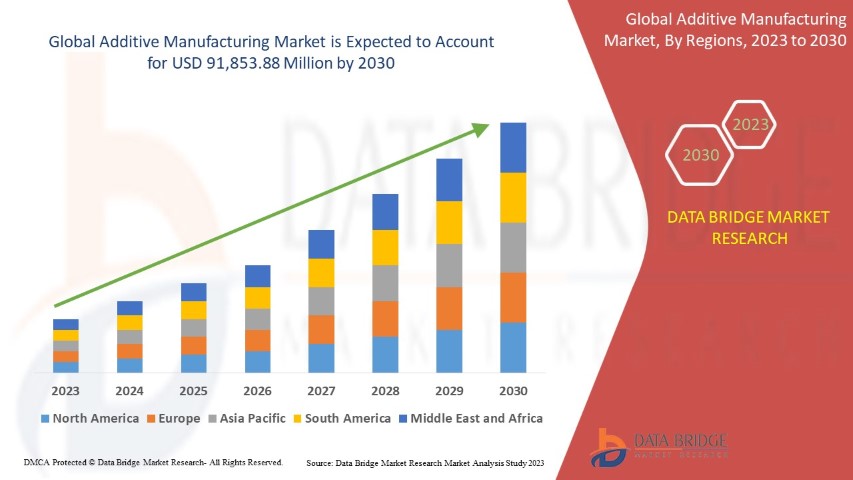

Additive Manufacturing Market Size

The additive manufacturing market size was valued at USD 91.84 billion in 2024 and is projected to reach USD 419.22 billion by 2032, with a CAGR of 20.90% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Additive Manufacturing Market Trends

“Increasing Use of Metal 3D Printing Technologies”

The increasing use of metal 3D printing technologies is reshaping the additive manufacturing market. Advancements in metal printing enhance precision, durability, and design flexibility across industries. Sectors such as aerospace, automotive, and healthcare increasingly adopt metal 3D printing for complex components. High-strength materials such as titanium and stainless steel improve performance and structural integrity. Enhanced printing techniques enable the production of lightweight parts with reduced material waste. Growing demand for customized metal components accelerates investments in industrial-grade 3D printers. Integration of AI-driven design optimization further enhances efficiency and manufacturing speed. For instance, aerospace firms utilize metal 3D printing to develop lightweight aircraft components. This adoption reduces production time while maintaining high mechanical strength and reliability. As industries recognize its benefits, metal 3D printing continues driving innovation in manufacturing processes.

Report Scope and Additive Manufacturing Market Segmentation

|

Attributes |

Additive Manufacturing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

ANSYS, Inc. (U.S.), Höganäs AB (Sweden), EOS (Germany), ARBURG GmbH + Co KG (Germany), Stratasys (U.S.), Renishaw plc. (U.K.), YAMAZAKI MAZAK CORPORATION (Japan), Materialise (Belgium), Markforged (U.S.), Titomic Limited. (Australia), SLM Solutions (Germany), Proto Labs (U.S.), ENVISIONTEC US LLC (U.S.), Ultimaker BV (Netherlands), American Additive Manufacturing LLC (U.S.), Optomec, Inc. (U.S.), 3D Systems Inc. (U.S.), and ExOne (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Additive Manufacturing Market Definition

Additive manufacturing (AM) is distinct from traditional subtractive manufacturing, which involves cutting or removing material from a solid block to form a product. In industrial settings, AM is commonly associated with 3D printing, a process that constructs objects layer by layer using a digital 3D model. This method enables precise fabrication by depositing material incrementally, guided by advanced 3D printer software. Various AM technologies, such as powder bed fusion, material extrusion, and vat photopolymerization, are selected based on application-specific requirements. Factors such as material properties, structural integrity, and production efficiency influence technology selection. Additive manufacturing offers advantages such as reduced material waste, complex geometries, and enhanced customization, making it a preferred choice in industries including aerospace, healthcare, and automotive.

Additive Manufacturing Market Dynamics

Drivers

- Cost Efficiency in Low-Volume Production

Cost efficiency in low-volume production is a key driver for the additive manufacturing market. Traditional manufacturing methods involve high tooling costs, making small-batch production expensive and inefficient. Additive manufacturing eliminates the need for molds and reduces material waste, lowering overall production expenses. This cost advantage enables businesses to produce customized components without incurring excessive setup costs. Industries such as aerospace and healthcare benefit from on-demand production, reducing inventory and storage costs. Additionally, additive manufacturing allows for rapid prototyping, accelerating product development cycles and minimizing resource consumption. For instance, medical device manufacturers use 3D printing to create patient-specific implants, ensuring cost-effective customization. The ability to produce complex geometries without additional expenses further strengthens its adoption. As companies seek flexible and economical production solutions, additive manufacturing continues to gain traction in low-volume manufacturing scenarios.

- Advancements in Material Innovation

Advancements in material innovation are driving growth in the additive manufacturing market. The development of high-performance materials enhances the strength, durability, and functionality of 3D-printed components. Expanding material options, including metals, polymers, and composites, enables broader industrial applications. Enhanced material properties improve thermal resistance, chemical stability, and mechanical performance for end-use products. Industries such as aerospace and healthcare benefit from lightweight yet strong materials for critical applications. For instance, titanium alloys in 3D printing support the production of durable and lightweight aircraft components. Additionally, biocompatible materials facilitate the development of customized medical implants and prosthetics. Continuous research in material science fosters new possibilities for manufacturing complex and high-precision parts. As companies demand superior performance and customization, material advancements continue to strengthen additive manufacturing adoption across various industries.

Opportunities

- Rising Government Grants and Incentives

Rising government grants and incentives present a significant opportunity in additive manufacturing. Increased funding supports research initiatives, accelerating advancements in printing technologies and material development. Governments worldwide offer financial aid to encourage industrial adoption, reducing implementation costs for manufacturers. Subsidies and tax benefits further enhance the affordability of high-performance 3D printing systems. Such initiatives promote localized production, strengthening supply chains and reducing dependency on imports. Public sector investments drive innovation in aerospace, healthcare, and automotive industries. For instance, government-backed programs in the U.S. and Europe facilitate large-scale additive manufacturing adoption. This financial backing encourages startups and established companies to expand operations. Increased funding fosters collaboration between academia, research institutions, and industrial players. Strengthened regulatory support also ensures technology standardization, promoting widespread market penetration. Continuous government investment is essential for unlocking the full potential of additive manufacturing.

- Growth in On-Demand Production

The increasing adoption of on-demand production presents a significant opportunity in additive manufacturing. This approach minimizes inventory costs by enabling real-time, customized production based on demand. Manufacturers can swiftly respond to market needs, reducing lead times and material wastage. The flexibility of additive manufacturing allows businesses to produce complex parts without extensive retooling. Industries such as aerospace, automotive, and healthcare benefit from rapid prototyping and low-volume production capabilities. For instance, automotive companies use 3D printing to manufacture spare parts on demand, reducing storage costs. The ability to localize production further enhances supply chain efficiency and cost-effectiveness. As companies shift towards more agile manufacturing models, the demand for additive manufacturing solutions continues to rise.

Restraints/Challenges

- High Initial Investment Costs

High initial investment costs remain a significant restraint in the additive manufacturing market. Setting up advanced 3D printing facilities requires substantial capital for industrial-grade printers and auxiliary equipment. The cost of high-performance materials further increases the financial burden on manufacturers. Small and medium enterprises (SMEs) face challenges in adopting additive manufacturing due to limited budgets. Additionally, expenses related to software, training, and skilled workforce add to operational costs. Industries requiring high-precision components must invest in advanced technologies, increasing overall expenditures. For instance, aerospace companies adopting metal 3D printing incur high costs for specialized machinery. The prolonged return on investment makes cost justification difficult for businesses. These financial constraints slow the widespread adoption of additive manufacturing technologies.

- Standardization and Certification Issues

Standardization and certification issues pose a significant challenge in the additive manufacturing market. The absence of universally accepted standards complicates material qualification and process validation. Industries such as aerospace and healthcare require stringent certifications to ensure component reliability. Lack of standardized testing methods creates inconsistencies in product quality and performance. Regulatory bodies are still developing guidelines for 3D-printed parts, delaying approvals. Manufacturers face difficulties in scaling production due to varying regional compliance requirements. For instance, medical device manufacturers must meet strict FDA or EU regulations before commercialization. Inconsistent certification processes lead to extended lead times and increased costs for businesses. Ensuring uniform standards is crucial to enhancing trust and accelerating market adoption. Addressing these issues will drive wider industrial acceptance and long-term growth.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Additive Manufacturing Market Scope

The market is segmented on the basis of material type, technology, and application. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Material Type

- Metal

- Plastic

- Alloys

- Ceramics

Technology

- Stereolithography (SLA)

- Fused Deposition Modeling (FDM)

- Laser Sintering (LS)

- Binder Jetting Printing

- Polyjet Printing

- Electron Beam Melting (EBM)

- Laminated Object Manufacturing (LOM)

- Others

Application

- Automotive

- Healthcare

- Aerospace

- Consumer Goods

- Industrial

- Defence

- Architecture

- Others

Additive Manufacturing Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, material type, technology, and application as referenced above.

The countries covered in the market report are U.S., Canada, Mexico in North America, Germany, Sweden, Poland, Denmark, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in Asia-Pacific (APAC), Brazil, Argentina, Rest of South America as a part of South America, U.A.E, Saudi Arabia, Oman, Qatar, Kuwait, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

North America holds the dominating position in the global additive manufacturing market during the forecast year of 2025-2032, with the U.S. at the forefront of this growth. The dominance of the U.S. in the region can be attributed to its advanced technological developments and innovations in 3D printing, which have fostered a robust ecosystem for additive manufacturing. In addition, a strong presence of key industry players, coupled with significant investments in research and development, has further propelled the U.S. to the top of the additive manufacturing landscape.

Asia Pacific is set for significant growth in the global additive manufacturing market during the forecast year of 2025-2032, with the regional market projected to achieve the highest CAGR during the forecast period. This growth can be primarily attributed to ongoing advancements and upgrades undertaken by key players in the manufacturing sector throughout the region. Asia Pacific is increasingly recognized as a manufacturing hub for industries such as automotive, healthcare, and consumer electronics. In addition, rapid urbanization is anticipated to play a crucial role in boosting the adoption of three-dimensional printing in the region over the forecast period.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Additive Manufacturing Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Additive Manufacturing Market Leaders Operating in the Market Are:

- ANSYS, Inc. (U.S.)

- Höganäs AB (Sweden)

- EOS (Germany)

- ARBURG GmbH + Co KG (Germany)

- Stratasys (U.S.)

- Renishaw plc. (U.K.)

- YAMAZAKI MAZAK CORPORATION (Japan)

- Materialise (Belgium)

- Markforged (U.S.)

- Titomic Limited (Australia)

- SLM Solutions (Germany)

- Proto Labs (U.S.)

- ENVISIONTEC US LLC (U.S.)

- Ultimaker BV (Netherlands)

- American Additive Manufacturing LLC (U.S.)

- Optomec, Inc. (U.S.)

- 3D Systems Inc. (U.S.)

- ExOne (U.S.)

Latest Developments in Additive Manufacturing Market

- In November 2023, Autodesk Inc. unveiled Autodesk AI, a new technology integrated into its products that provides generative capabilities and intelligent assistance. This innovation is intended to reduce errors by automating repetitive tasks and addressing customer needs

- In March 2023, 3D Systems, Inc. introduced two new printing materials, NextDent Cast and NextDent Base, along with the NextDent LCD1 printing platform, designed to improve material properties and offer an easy-to-use small-format printer. These launches aim to assist customers in accelerating the adoption of additive manufacturing

- In October 2022, GE Additive, a U.S.-based company, launched its new Series 3 binder jet platform, designed for the industrial-scale production of metal parts such as castings. The company has produced over 140,000 of these components, which offer 15% greater fuel efficiency compared to standard alternatives

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Additive Manufacturing Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Additive Manufacturing Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Additive Manufacturing Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.