Global 3d Printing Materials Market

Market Size in USD Billion

CAGR :

%

USD

3.13 Billion

USD

13.56 Billion

2024

2032

USD

3.13 Billion

USD

13.56 Billion

2024

2032

| 2025 –2032 | |

| USD 3.13 Billion | |

| USD 13.56 Billion | |

|

|

|

|

3D Printing Materials Market Size

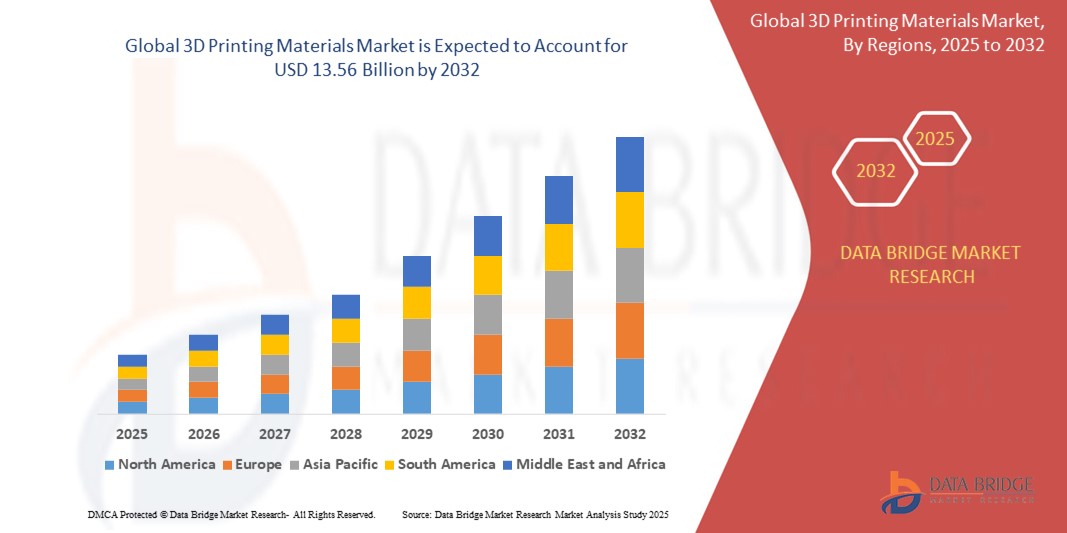

- The global 3D printing materials market size was valued at USD 3.13 billion in 2024 and is expected to reach USD 13.56 billion by 2032, at a CAGR of 20.10% during the forecast period

- The market growth is largely fueled by the expanding use of 3D printing across key industries such as aerospace, automotive, and healthcare, supported by advancements in additive manufacturing technologies and material science

- Furthermore, the increasing demand for lightweight, high-performance, and customizable components is driving innovation in materials such as metals, polymers, and composites, accelerating the adoption of 3D printing materials and significantly boosting the industry's growth

3D Printing Materials Market Analysis

- 3D printing materials, encompassing polymers, metals, and ceramics, are essential components in additive manufacturing processes across various sectors due to their ability to enable rapid prototyping, customization, and production of complex geometries with reduced waste

- The escalating demand for 3D printing materials is primarily fueled by increasing industrial adoption of additive manufacturing, advancements in material properties, and the growing need for cost-efficient, on-demand production solutions

- North America dominated the 3D printing materials market with a share of 39.5% in 2024, due to the strong presence of leading additive manufacturing companies, high R&D investments, and widespread adoption across industries such as aerospace, healthcare, and automotive

- Asia-Pacific is expected to be the fastest growing region in the 3D printing materials market during the forecast period due to expanding industrialization, government backing for digital technologies, and the rising affordability of 3D printing systems and materials

- Plastics/polymers segment dominated the market with a market share of 38.4% in 2024, due to its widespread use across both consumer and industrial applications. Thermoplastics such as PLA, ABS, and nylon are highly favored for their affordability, ease of use, and versatility across multiple 3D printing technologies. Their mechanical properties, recyclability, and suitability for prototyping and functional part production have further strengthened their dominance in educational, design, and consumer goods sectors

Report Scope and 3D Printing Materials Market Segmentation

|

Attributes |

3D Printing Materials Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

3D Printing Materials Market Trends

“Rising Use of Sustainable and Recycled Materials in Additive Manufacturing”

- A significant and accelerating trend in the global 3D printing materials market is the shift toward sustainable materials, including bio-based polymers and recycled composites, in response to rising environmental awareness and industry pressure to reduce waste and emissions

- For instance, in June 2023, CRP Technology launched Windform XT 2.0 IMG, a high-performance injection molding material made entirely from recycled Windform XT 2.0, enabling seamless transitions from prototyping to production while reducing carbon footprints

- The adoption of eco-friendly materials is being driven by increasing regulatory requirements, corporate sustainability goals, and demand for greener supply chains. Companies are investing in closed-loop manufacturing and lifecycle material reuse to minimize environmental impact

- The incorporation of sustainable 3D printing materials is gaining momentum across industries such as aerospace, automotive, and consumer goods, where sustainability credentials play a growing role in supplier selection and product development strategies

- Leading material manufacturers such as BASF, Arkema, and Stratasys are expanding their portfolios of sustainable materials, reinforcing the market shift towards greener alternatives that offer performance without environmental compromise

- This trend toward recyclable and bio-based 3D printing materials is fundamentally reshaping the additive manufacturing landscape, encouraging more circular production models and boosting the adoption of 3D printing in sustainability-driven industries

3D Printing Materials Market Dynamics

Driver

“Expanding Adoption of Additive Manufacturing Across Key Industrial Sectors”

- The growing utilization of additive manufacturing across automotive, aerospace, and healthcare sectors is a key driver accelerating demand for high-performance 3D printing materials that can support complex, lightweight, and customized applications

- For instance, the April 2023 acquisition of Covestro’s additive manufacturing materials business by Stratasys expanded its portfolio with around 60 new materials, enabling it to better serve aerospace and healthcare applications

- Industries are leveraging 3D printing for rapid prototyping, tooling, and end-use part production, benefiting from reduced lead times, minimized waste, and improved design flexibility offered by advanced materials

- In aerospace, materials such as carbon fiber composites and metal powders are critical for producing lightweight components with superior strength-to-weight ratios, while in healthcare, biocompatible polymers and resins enable custom medical implants and devices

- This widespread industrial adoption, paired with technological advancements and broader material availability, continues to drive market growth, positioning 3D printing materials as a cornerstone of next-generation manufacturing strategies

Restraint/Challenge

“High Material Costs and Limited Standardization”

- The high cost of advanced 3D printing materials, including specialty metal powders, engineered polymers, and high-performance composites, poses a significant barrier to wider adoption, particularly among small- and medium-sized enterprises

- For instance, while polymers such as PEEK and ULTEM offer superior heat resistance and mechanical properties, their high price compared to conventional thermoplastics limits their use to niche applications in aerospace and medical sectors

- The lack of standardized quality benchmarks and performance specifications across material suppliers also contributes to procurement complexity and hinders large-scale adoption in regulated industries such as healthcare and defense

- Furthermore, limitations in material compatibility with different 3D printing technologies restrict end-user flexibility, forcing organizations to invest in multiple machines or compromise on performance

- To overcome these challenges, manufacturers are focusing on cost reduction through economies of scale, enhanced material formulations, and the development of certification protocols for consistent quality, but adoption barriers remain a concern in price-sensitive and high-regulation markets

3D Printing Materials Market Scope

The market is segmented on the basis of type, form, technology, and end-use.

• By Type

On the basis of type, the 3D printing materials market is segmented into plastics/polymers, metal, ceramic, and others. The plastics/polymers segment dominated the largest market revenue share of 38.4% in 2024, primarily due to its widespread use across both consumer and industrial applications. Thermoplastics such as PLA, ABS, and nylon are highly favored for their affordability, ease of use, and versatility across multiple 3D printing technologies. Their mechanical properties, recyclability, and suitability for prototyping and functional part production have further strengthened their dominance in educational, design, and consumer goods sectors.

The metal segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by rising demand in high-performance applications in aerospace, automotive, and healthcare industries. Metal materials such as titanium, stainless steel, and aluminum enable the production of strong, lightweight, and complex parts, which are difficult to manufacture through conventional methods. Increasing adoption of metal additive manufacturing in the production of critical components and implants is boosting segmental growth.

• By Form

On the basis of form, the market is categorized into powder, filament, and liquid. The filament segment accounted for the largest revenue share in 2024, owing to its dominance in consumer and desktop 3D printing. Filament-based materials are cost-effective, easy to handle, and compatible with widely used FDM printers, making them the preferred choice for rapid prototyping and hobbyist applications. The availability of a broad range of filament materials with varying mechanical and aesthetic properties further supports its widespread adoption.

The powder segment is expected to record the highest CAGR from 2025 to 2032, propelled by its critical role in industrial-grade printing technologies such as SLS and DMLS. Powder-based materials enable precise layering, higher resolution, and structural integrity, making them suitable for complex, high-strength components used in aerospace, medical implants, and tooling applications.

• By Technology

Based on technology, the 3D printing materials market is segmented into FDM, SLS, SLA, DMLS, BAAM, WAAM, ColorJet, and others. Fused Deposition Modeling (FDM) held the largest market share in 2024 due to its cost-effectiveness, material availability, and widespread usage across educational, consumer, and prototyping applications. Its compatibility with various thermoplastic filaments and ease of use in desktop printers have led to its widespread deployment globally.

Direct Metal Laser Sintering (DMLS) is projected to witness the fastest growth during 2025–2032, owing to its increasing adoption in high-precision, metal part manufacturing across industries such as aerospace, automotive, and medical. DMLS enables the creation of complex geometries and highly durable parts directly from metal powders, offering a transformative advantage over subtractive manufacturing methods.

• By End-Use

By end-use, the market is segmented into industrial manufacturing, automotive, healthcare, aerospace & defense, consumer goods, electronics, education, construction, and others. The industrial manufacturing segment accounted for the highest revenue in 2024, attributed to growing use of 3D printing materials in tooling, jigs and fixtures, and custom part fabrication. The ability to rapidly iterate designs, lower material waste, and reduce lead times has made additive manufacturing an integral part of modern industrial workflows.

The healthcare segment is projected to register the fastest CAGR from 2025 to 2032, fueled by growing applications in patient-specific implants, dental prosthetics, anatomical models, and bioprinting. The precision and customization enabled by 3D printing, coupled with the development of biocompatible materials, are transforming the way personalized care is delivered in medical settings.

3D Printing Materials Market Regional Analysis

- North America dominated the 3D printing materials market with the largest revenue share of 39.5% in 2024, driven by the strong presence of leading additive manufacturing companies, high R&D investments, and widespread adoption across industries such as aerospace, healthcare, and automotive

- The region benefits from advanced technological infrastructure and a high concentration of innovation-driven manufacturing, supporting large-scale use of polymers, metals, and advanced composites

- Government initiatives promoting digital manufacturing and the presence of early adopters further solidify North America’s leadership in the 3D printing materials space, especially in industrial and medical applications

U.S. 3D Printing Materials Market Insight

The U.S. 3D printing materials market captured the largest revenue share in 2024 within North America, fueled by the robust expansion of additive manufacturing across aerospace, defense, and medical sectors. The country's innovation ecosystem, backed by leading 3D printer manufacturers and research institutions, promotes material development for high-performance applications. Increasing demand for customized implants, lightweight vehicle parts, and advanced prototyping continues to drive the consumption of both metal and polymer-based materials across industries.

Europe 3D Printing Materials Market Insight

Europe 3D printing materials market is projected to expand at a notable CAGR throughout the forecast period, supported by a strong manufacturing base, sustainability-driven innovations, and government-led digital transformation initiatives. European companies are increasingly focusing on bio-based polymers, recyclable materials, and efficient production methods to reduce environmental impact while meeting high regulatory standards. The region’s growth is reinforced by rising adoption in automotive and medical sectors, alongside expanding use in consumer goods and educational applications

U.K. 3D Printing Materials Market Insight

The U.K. 3D printing materials market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing investment in Industry 4.0 technologies and demand for localized, rapid manufacturing. The country’s healthcare and aerospace sectors are actively embracing additive manufacturing, boosting the use of advanced polymers and metal powders. Government-supported initiatives and academic-industry collaborations are fostering material innovation and commercialization.

Germany 3D Printing Materials Market Insight

The Germany 3D printing materials market is expected to expand at a considerable CAGR during the forecast period, backed by its strong industrial base, emphasis on engineering excellence, and innovation in material science. Germany is at the forefront of metal additive manufacturing and is investing heavily in research related to high-performance alloys, ceramic composites, and sustainable polymers. Demand from automotive, tooling, and medical sectors continues to fuel the need for specialized materials.

Asia-Pacific 3D Printing Materials Market Insight

Asia-Pacific 3D printing materials market is poised to grow at the fastest CAGR during the forecast period of 2025 to 2032, driven by expanding industrialization, government backing for digital technologies, and the rising affordability of 3D printing systems and materials. Rapid economic growth, particularly in China, Japan, and India, is supporting adoption across sectors including education, electronics, construction, and healthcare. The region also benefits from a strong base of material suppliers and growing domestic production, making 3D printing more accessible to small and mid-sized businesses

Japan 3D Printing Materials Market Insight

The Japan 3D printing materials market is witnessing steady growth due to the country's focus on precision engineering, miniaturization, and smart manufacturing. High demand from the electronics, medical device, and automotive sectors is pushing the development of functional polymers and advanced ceramics. Japan’s strategic emphasis on sustainability and advanced material performance is accelerating adoption, especially in research-driven and export-oriented industries.

China 3D Printing Materials Market Insight

The China 3D printing materials market accounted for the largest revenue share in Asia-Pacific in 2024, supported by aggressive investment in manufacturing technologies and rising consumer demand for 3D printed products. The country’s extensive domestic production capacity and policy incentives for innovation are encouraging the use of polymers, metals, and ceramic materials. As part of China’s smart manufacturing strategy, 3D printing is being integrated across automotive, healthcare, and consumer electronics sectors, fueling material demand.

3D Printing Materials Market Share

The 3D printing materials industry is primarily led by well-established companies, including:

- Formlabs (U.S.)

- EOS (Germany)

- ENVISIONTEC US LLC (U.S.)

- American Elements (U.S.)

- Höganäs AB (Sweden)

- UltiMaker (Netherlands)

- Carbon, Inc. (U.S.)

- KRAIBURG TPE GmbH & Co. KG (Germany)

- Covestro AG (Germany)

- Markforged, Inc. (U.S.)

- Stratasys (U.S./Israel)

- ExOne (U.S.)

- Arkema (France)

- 3D Systems, Inc. (U.S.)

- Evonik Industries AG (Germany)

- Materialise (Belgium)

- BASF (Germany)

- Sandvik AB (Sweden)

- Solvay (Belgium)

Latest Developments in Global 3D Printing Materials Market

- In October 2023, EOS launched its Digital Foam Architects network, designed to accelerate the development and additive manufacturing (AM) of consumer, medical and industrial products featuring Digital Foam applications. Digital Foam is not a product, rather it is an approach to 3D printing foam-like products. It will provide a new direction to the company in 3D printing materials

- In June 2023, CRP Technology launched Windform XT 2.0 IMG, the first injection molding material made entirely from recycled Windform XT 2.0 3D printing materials. This carbon fiber-reinforced nylon PA12 composite supports the market’s shift toward sustainable manufacturing by enabling a seamless transition from prototyping to mass production while lowering environmental impact. The innovation strengthens the 3D printing materials market by aligning with growing demand for eco-friendly, high-performance solutions in industrial applications

- In April 2023, Stratasys completed the acquisition of Covestro’s additive manufacturing materials business, adding approximately 60 advanced materials and a strong IP portfolio to its offerings. This move significantly enhances Stratasys’ position in the 3D printing materials market by broadening its reach in sectors such as aerospace and healthcare. The acquisition boosts innovation capacity, particularly in stereolithography and powder bed fusion technologies, thereby accelerating market growth and competitive differentiation

- In February 2023, Bauer Hockey, the global leader in hockey equipment innovation, and industrial 3D printing industry pioneer and market leader, EOS, have collaborated to incorporate additive manufacturing (AM, or 3D printing) into Bauer’s MyBauer custom equipment program. EOS and its patented Digital Foam approach to printing polymers gave Bauer a distinct advantage. It will strengthen the market presence for EOS in the 3D printing materials market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 CURRENCY AND PRICING

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 MULTIVARIATE MODELING

2.7 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.8 DBMR MARKET POSITION GRID

2.9 MARKET END USER COVERAGE GRID

2.1 DBMR VENDOR SHARE ANALYSIS

2.11 SECONDARY SOURCES

2.12 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTER’S FIVE FORCES

4.1.1 THREAT OF NEW ENTRANTS

4.1.2 THREAT OF SUBSTITUTES

4.1.3 BARGAINING POWER OF BUYERS

4.1.4 BARGAINING POWER OF SUPPLIERS

4.1.5 COMPETITIVE RIVALRY

4.2 PRICE TREND ANALYSIS

4.3 PRODUCTION CONSUMPTION ANALYSIS

4.3.1 ESTIMATED PRODUCTION CONSUMPTION ANALYSIS

4.4 SUPPLY CHAIN ANALYSIS

4.4.1 OVERVIEW

4.4.1.1 RAW MATERIAL SUPPLIERS

4.4.1.2 MATERIAL MANUFACTURERS

4.4.1.3 DISTRIBUTION AND LOGISTICS

4.4.1.4 3D PRINTER MANUFACTURERS

4.4.1.5 END-USERS

4.4.1.6 RESEARCH AND DEVELOPMENT

4.4.1.7 REGULATORY COMPLIANCE AND QUALITY ASSURANCE

4.4.2 LOGISTIC COST SCENARIO

4.4.3 IMPORTANCE OF LOGISTICS SERVICE PROVIDERS

4.5 TECHNOLOGICAL ADVANCEMENTS BY MANUFACTURERS

4.6 IMPORT-EXPORT ANALYSIS (USD THOUSAND)

4.6.1 IMPORT DATA

4.6.2 EXPORT DATA

5 REGULATION COVERAGE

6 MARKET OVERVIEW

6.1 DRIVERS

6.1.1 INCREASED ADOPTION OF 3D PRINTING IN VARIOUS INDUSTRIES

6.1.2 RISE IN PROTOTYPING AND RAPID TOOLING

6.1.3 EXPANDING ACCESSIBILITY AND AFFORDABILITY OF 3D PRINTING TECHNOLOGIES

6.1.4 DEVELOPMENT OF NEW MATERIALS WITH DIFFERENT PROPERTIES AND APPLICATIONS

6.2 RESTRAINTS

6.2.1 STRINGENT STANDARDIZATION, REGULATIONS AND CERTIFICATIONS ASSOCIATED WITH 3D PRINTING MATERIALS

6.2.2 LACK OF SKILLED LABORS IN 3D PRINTING SECTOR

6.3 OPPORTUNITIES

6.3.1 ADVANCEMENTS IN 3D PRINTING TECHNOLOGIES

6.3.2 EXTENSIVE DEMAND FOR BIOCOMPATIBLE MATERIALS FOR MEDICAL APPLICATIONS

6.3.3 EASE OF PERSONALIZATION AND CUSTOMIZATION OF PRODUCTS

6.4 CHALLENGES

6.4.1 HIGH COSTS ASSOCIATED WITH ADVANCED OR SPECIALTY 3D PRINTING MATERIALS

6.4.2 EXTENSIVE POST-PROCESSING REQUIREMENTS

7 GLOBAL 3D PRINTING MATERIALS MARKET, BY TYPE

7.1 OVERVIEW

7.2 PLASTICS/POLYMERS

7.3 METAL

7.4 CERAMIC

7.5 OTHERS

8 GLOBAL 3D PRINTING MATERIALS MARKET, BY FORM

8.1 OVERVIEW

8.2 POWDER

8.3 FILAMENT

8.4 LIQUID

9 GLOBAL 3D PRINTING MATERIALS MARKET, BY TECHNOLOGY

9.1 OVERVIEW

9.2 FUSED DEPOSITION MODELING (FDM)

9.3 SELECTIVE LASER SINTERING (SLS)

9.4 STEREOLITHOGRAPHY (SLA)

9.5 DIRECT METAL LASER SINTERING (DMLS)

9.6 BIG AREA ADDITIVE MANUFACTURING (BAAM)

9.7 WIRE ARC ADDITIVE MANUFACTURING (WAAM)

9.8 COLORJET

9.9 OTHERS

10 GLOBAL 3D PRINTING MATERIALS MARKET, BY END-USE

10.1 OVERVIEW

10.2 INDUSTRIAL MANUFACTURING

10.3 AUTOMOTIVE

10.4 HEALTHCARE

10.5 AEROSPACE & DEFENSE

10.6 CONSUMER GOODS

10.7 ELECTRONICS

10.8 EDUCATION

10.9 CONSTRUCTION

10.1 OTHERS

11 GLOBAL 3D PRINTING MATERIALS MARKET, BY REGION

11.1 OVERVIEW

1.1 NORTH AMERICA

11.1.1 U.S.

11.1.2 CANADA

11.1.3 MEXICO

11.2 EUROPE

11.2.1 GERMANY

11.2.2 ITALY

11.2.3 U.K.

11.2.4 FRANCE

11.2.5 SPAIN

11.2.6 TURKEY

11.2.7 RUSSIA

11.2.8 SWITZERLAND

11.2.9 BELGIUM

11.2.10 NETHERLANDS

11.2.11 LUXEMBOURG

11.2.12 REST OF EUROPE

11.3 ASIA PACIFIC

11.3.1 CHINA

11.3.2 JAPAN

11.3.3 INDIA

11.3.4 SOUTH KOREA

11.3.5 SINGAPORE

11.3.6 INDONESIA

11.3.7 THAILAND

11.3.8 PHILIPPINES

11.3.9 AUSTRALIA & NEW ZEALAND

11.3.10 MALAYSIA

11.3.11 REST OF ASIA-PACIFIC

11.4 MIDDLE EAST AND AFRICA

11.4.1 UNITED ARAB EMIRATES

11.4.2 SAUDI ARABIA

11.4.3 EGYPT

11.4.4 SOUTH AFRICA

11.4.5 ISRAEL

11.4.6 REST OF MIDDLE EAST AND AFRICA

11.5 SOUTH AMERICA

11.5.1 BRAZIL

11.5.2 ARGENTINA

11.5.3 REST OF SOUTH AMERICA

12 GLOBAL 3D PRINTING MATERIALS MARKET: COMPANY LANDSCAPE

12.1 COMPANY SHARE ANALYSIS: GLOBAL

12.2 COMPANY SHARE ANALYSIS: EUROPE

12.3 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

12.4 COMPANY SHARE ANALYSIS: NORTH AMERICA

13 SWOT ANALYSIS

14 COMPANY PROFILES

14.1 STRATASYS

14.1.1 COMPANY SNAPSHOT

14.1.2 REVENUE ANALYSIS

14.1.3 COMPANY SHARE ANALYSIS

14.1.4 PRODUCT PORTFOLIO

14.1.5 RECENT DEVELOPMENTS

14.2 EOS

14.2.1 COMPANY SNAPSHOT

14.2.2 COMPANY SHARE ANALYSIS

14.2.3 PRODUCT PORTFOLIO

14.2.4 RECENT DEVELOPMENTS

14.3 3D SYSTEMS, INC.

14.3.1 COMPANY SNAPSHOT

14.3.2 REVENUE ANALYSIS

14.3.3 COMPANY SHARE ANALYSIS

14.3.4 PRODUCT PORTFOLIO

14.3.5 RECENT DEVELOPMENTS

14.4 BASF SE

14.4.1 COMPANY SNAPSHOT

14.4.2 REVENUE ANALYSIS

14.4.3 COMPANY SHARE ANALYSIS

14.4.4 PRODUCT PORTFOLIO

14.4.5 RECENT DEVELOPMENT

14.5 FORMLABS

14.5.1 COMPANY SNAPSHOT

14.5.2 COMPANY SHARE ANALYSIS

14.5.3 PRODUCT PORTFOLIO

14.5.4 RECENT DEVELOPMENTS

14.6 AMERICAN ELEMENTS

14.6.1 COMPANY SNAPSHOT

14.6.2 PRODUCT PORTFOLIO

14.6.3 RECENT DEVELOPMENTS

14.7 ARKEMA

14.7.1 COMPANY SNAPSHOT

14.7.2 REVENUE ANALYSIS

14.7.3 PRODUCT PORTFOLIO

14.7.4 RECENT DEVELOPMENT

14.8 CARBON, INC.

14.8.1 COMPANY SNAPSHOT

14.8.2 PRODUCT PORTFOLIO

14.8.3 RECENT DEVELOPMENTS

14.9 COVESTRO AG

14.9.1 COMPANY SNAPSHOT

14.9.2 REVENUE ANALYSIS

14.9.3 PRODUCT PORTFOLIO

14.9.4 RECENT DEVELOPMENTS

14.1 ENVISIONTEC US LLC

14.10.1 COMPANY SNAPSHOT

14.10.2 PRODUCT PORTFOLIO

14.10.3 RECENT DEVELOPMENTS

14.11 EVONIK INDUSTRIES AG

14.11.1 COMPANY SNAPSHOT

14.11.2 REVENUE ANALYSIS

14.11.3 PRODUCT PORTFOLIO

14.11.4 RECENT DEVELOPMENTS

14.12 EXONE

14.12.1 COMPANY SNAPSHOT

14.12.2 PRODUCT PORTFOLIO

14.12.3 RECENT DEVELOPMENTS

14.13 HÖGANÄS AB

14.13.1 COMPANY SNAPSHOT

14.13.2 PRODUCT PORTFOLIO

14.13.3 RECENT DEVELOPMENTS

14.14 KRAIBURG TPE GMBH & CO. KG

14.14.1 COMPANY SNAPSHOT

14.14.2 PRODUCT PORTFOLIO

14.14.3 RECENT DEVELOPMENTS

14.15 MARKFORGED, INC.

14.15.1 COMPANY SNAPSHOT

14.15.2 REVENUE ANALYSIS

14.15.3 PRODUCT PORTFOLIO

14.15.4 RECENT DEVELOPMENTS

14.16 MATERIALISE

14.16.1 COMPANY SNAPSHOT

14.16.2 REVENUE ANALYSIS

14.16.3 PRODUCT PORTFOLIO

14.16.4 RECENT DEVELOPMENT

14.17 SANDVIK AB

14.17.1 COMPANY SNAPSHOT

14.17.2 REVENUE ANALYSIS

14.17.3 PRODUCT PORTFOLIO

14.17.4 RECENT DEVELOPMENT

14.18 SOLVAY

14.18.1 COMPANY SNAPSHOT

14.18.2 REVENUE ANALYSIS

14.18.3 PRODUCT PORTFOLIO

14.18.4 RECENT DEVELOPMENT

14.19 ULTIMAKER

14.19.1 COMPANY SNAPSHOT

14.19.2 PRODUCT PORTFOLIO

14.19.3 RECENT DEVELOPMENTS

15 QUESTIONNAIRE

16 RELATED REPORTS

Global 3d Printing Materials Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global 3d Printing Materials Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global 3d Printing Materials Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.