Asia Pacific Industrial Valves Market

Market Size in USD Million

CAGR :

%

USD

77,081.35 Million

USD

124,722.69 Million

2022

2030

USD

77,081.35 Million

USD

124,722.69 Million

2022

2030

| 2023 –2030 | |

| USD 77,081.35 Million | |

| USD 124,722.69 Million | |

|

|

|

Asia-Pacific Industrial Valves Market Analysis and Size

The flow of liquids, gases, slurries, and other substances through pipes and tubes is controlled by industrial valves, which are mechanical or electromechanical components used in a variety of industries. Various industrial valve types have shut-on/off requirements, pressure control, and other regulatory requirements as their functions. Processes are controlled, regulated, and turned on and off using industrial valves. Industrial valves can also be made from metal alloys such as carbon steel, cast iron, stainless steel, and others for high efficiency. Additionally, industrial valves with high levels of automation and control operate more effectively in risky settings such as nuclear power plants, oil and gas fields, and chemical processing. The automation of technology has also decreased.

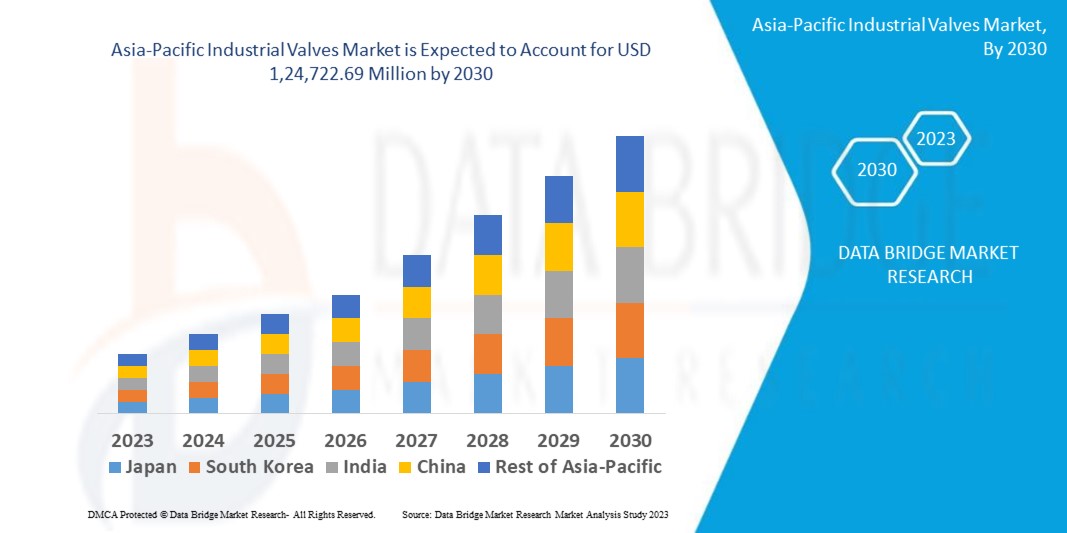

Data Bridge Market Research analyses that the industrial valves market, valued at USD 77,081.35 million in 2022, will reach USD 1,24,722.69 million by 2030, growing at a CAGR of 6.2% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Asia-Pacific Industrial Valves Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015 - 2020) |

|

Quantitative Units |

Revenue in USD Million, Volumes in Units, Pricing in USD |

|

Segments Covered |

Components (Actuators, Valve Body, Others), Type (Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, Diaphragm Valve, Check Valve, Plug Valve, Pinch Valve, Needle Valve, Pressure Relief Valve, Safety Valve, Others), Function (On/Off, Control, Isolation, Regulation Safety Relief Valve, Special Purpose, Non-Return), Material (Iron, Carbon Steel, Alloy, Plastic, Brass, Bronze, Copper, Cryogenic, Aluminium, Others), Accessories (Hydraulic Filter, Power Cable, Mounting Screw and Bolts, Seal Kits, Dust Protection Cover, Others), Size (1 Inch to 6 Inch, 6 Inch to 12 Inch, 12 Inch to 24 Inch, 24 Inch to 48 Inch, Above 48 Inch), Application (Oil and Gas, Building and Construction, Semiconductors, Water and Waste Treatment, Chemical, Energy and Utilities, Food and Beverages, Pharmaceutical, Agriculture, Marine, Automotive, Metals and Mining, Paper and Pulp, Others) |

|

Countries Covered |

China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC) |

|

Market Players Covered |

Emerson Electric Co. (U.S.), Flowserve Corporation (U.S.), Crane Company (U.S.), IMI (U.K.), Velan Inc. (Canada), KITZ Corporation (Japan), Neway valve (China), AVK Holding A/S (Denmark), Metso (Finland), Spirax Sarco Limited. (U.K.), Johnson Controls International plc (Ireland), Powell Valves (U.S.), Curtiss-Wright. (U.S.), Mueller Co. LLC. (U.S.), Crane Co., CRANE ChemPharma & Energy Corp (U.S.), The Weir Group PLC (U.K.), Wärtsilä (Finland), Bray International (U.S.), Dwyer Instruments LTD (U.S.), Watts. (U.S.), Bonney Forge Corporation (U.S.), NIBCO Inc. (U.S.) |

|

Market Opportunities |

|

Market Definition

Businesses use mechanical industrial valves to regulate the flow of liquids, gases, and slurries through piping systems. They can regulate the flow by enlarging, constricting, or partially obstructing the passage. They can also control temperature, pressure, and backflow. Gate valves, globe valves, ball valves, and butterfly valves are just a few of the different sizes and types of valves. By controlling fluid flow and preserving system integrity, they are crucial components in sectors such as oil and gas, water treatment, power generation, and manufacturing, ensuring the safe and effective operation of processes.

Asia-Pacific Industrial Valves Market Dynamics

Drivers

- Industrial growth drives the market

The continual growth of industries such as oil and gas, petrochemicals, power generation, water and wastewater treatment, and manufacturing is driving up demand for industrial valves. As these industries grow, so does the requirement for valves to regulate fluid flow, control process parameters, and ensure efficient and secure operations. Valves are essential components in these industries for tasks such as starting, stopping, and modulating fluid flow, maintaining pressure and temperature levels, and preventing backflow or leakage. Both the expansion of these industries' infrastructure and their industrial activities have a direct impact on the rise in demand for industrial valves to support their expanding operations.

- Technological advancement drives the market growth

The demand for industrial valves is significantly impacted by technological developments in valve design, materials, and automation. These developments give valves new functionalities and features that improve their efficiency, dependability, and control. Fluid flow is optimized in better designs, which lowers energy use and boosts efficiency. Advanced materials offer improved fluid compatibility, corrosion resistance, and toughness. Automation technologies make it possible to operate, monitor, and integrate with control systems remotely, which boosts the effectiveness and control of processes. In an effort to take advantage of these developments and improve overall performance, lower maintenance costs, and optimize their processes for greater productivity and operational excellence, industries upgrade their current valves or invest in new ones.

Opportunities

- Rising environmental concerns allows market expansion

Rising environmental awareness and the emphasis on sustainability have increased the demand for industrial valves in green technologies. These valves are crucial for streamlining operations and minimizing their negative effects on the environment in procedures such as pollution control, wastewater treatment, and the creation of renewable energy. Valves are used to regulate fluid flow in hydroelectric power plants, wind turbine cooling systems, and solar thermal systems. The use of valves in wastewater treatment enables efficient and environmentally friendly treatment by controlling flow and treatment processes. By controlling emissions, preventing leaks, and maintaining process effectiveness, valves aid in pollution control efforts in line with the growing emphasis on environmental sustainability.

- Globalization and international trade surge market expansion

Industrial globalization and increased international trade, supply chains have expanded and demand for industrial valves has increased. Valves are crucial components in the logistics and shipping sectors, where goods are transported, processed, and stored. The efficient control of fluid flow in tanks, containers, and pipelines by valves makes it possible to transport a variety of goods safely. The demand for valves in ports, terminals, warehouses, and transportation networks rises along with the volume of global trade, which boosts the demand for industrial valves as a whole. These valves are used to manage and regulate the transportation of goods between different geographical areas.

Restraints/Challenges

- Technological obsolescence restricts the market growth

Through quickly technology advances, the industrial valve industry is restricted by technological obsolescence. As new technologies develop, older valve designs and features may become ineffective and incompatible with modern control systems. In order to ensure that their valves are efficient, dependable, and flexible enough to adapt to changing industrial processes, industries must stay abreast of technological advancements. Inability to adapt to new technologies may result in lower productivity, increased maintenance costs, and potential system failures. Continuous technological advancement monitoring and proactive valve upgrade spending are needed to lower the risk of technological obsolescence and maintain market competitiveness.

- High cost and need for regular maintenance limit the growth

The price of industrial valves and the associated costs of installation, maintenance, and repair can be a significant constraint on projects or industries with limited budgets. Industrial valves, especially those with larger or more complex designs, can be expensive up front. Regular maintenance and sporadic repairs are also necessary to guarantee the best valve performance. These processes frequently involve downtime, which can reduce operational effectiveness and disrupt production, especially in industries with continuous processes. The costs associated with valve maintenance and repair, as well as the resulting downtime, can present challenges and financial constraints for industries trying to strike a balance between cost-effectiveness and uninterrupted operations.

This industrial valves market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the industrial valves market contact Data Bridge Market Research for an analyst brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Recent Developments

- In 2022, The Crosby J series pressure relief valve product line was introduced by Emerson, and it is meant to ensure balanced operations against backpressure in order to boost performance and reduce ownership costs. They have a bellows leak detection system, which allows for remote detection of bellows ruptures in the valves and lowers volumetric emission.

- In 2022, The series of additively manufactured/3D printed diaphragm values made of unique alloy material were introduced by KSB SE & CO. KGaA. The pharmaceutical industry was the focus of the new valves' design.

- In 2022, The valve and pulp businesses of Flowrox, a technology company with headquarters in Finland, have been acquired by Neles, a leading provider of flow control solutions worldwide. Neles wants to increase its product offering and exposure to the mining and metals sector through this acquisition.

- In 2022, Meggitt PLS, a global leader in the aerospace, defense, and energy markets, was successfully acquired by Parker Hannifin Corporation. Industrial valves and control systems are among the wide range of technologies and goods it offers.

- In 2020, The U.S. Environmental Protection Agency presented the Energy Star Partner of the Year Award to Hayward Industries, Inc., a company that manufactures equipment for residential and commercial swimming pools. According to tests, Hayward provides the pool with variable-speed pumps that are the most energy-efficient. The company will benefit from this award in terms of increased brand value and global recognition.

Asia-Pacific Industrial Valves Market Scope

The industrial valves market is segmented on the basis of component, type, function, material, accessories, size, application, The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Components

- Actuators

- Valve Body

- Others

- Positioners

- I/P Converters

Type

- Gate Valve

- Globe Valve

- Ball Valve

- Butterfly Valve

- Diaphragm Valve

- Check Valve

- Plug Valve

- Pinch Valve

- Needle Valve

- Pressure Relief Valve

- Safety Valve

- Others

Function

- On/Off

- Control

- Isolation

- Regulation

- Safety Relief Valve

- Special Purpose

- Non-Return

Material

- Iron

- Ductile

- Cast Iron

- Carbon Steel

- Alloy

- Plastic

- Brass

- Bronze

- Copper

- Cryogenic

- Aluminium

- Others

Accessories

- Hydraulic Filter

- Power Cable

- Mounting Screw and Bolts

- Seal Kits

- Dust Protection Cover

- Others

Size

- 1 Inch to 6 Inch

- 6 Inch to 12 Inch

- 12 Inch to 24 Inch

- 24 Inch to 48 Inch

- Above 48 Inch

Application

- Oil and Gas

- Building and Construction

- Semiconductors

- Water and Waste Treatment

- Chemical

- Energy and Utilities

- Food and Beverages

- Pharmaceutical

- Agriculture

- Marine

- Automotive

- Metals and Mining

- Paper and Pulp

- Others

- Textile

- Glass

Industrial Valves Market Regional Analysis/Insights

The industrial valves market is analysed and market size insights and trends are provided by country, component, type, function, material, accessories, size, and application as referenced above.

The countries covered in the industrial valves market report are China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, and Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC)

China accounted the largest market share due to growing industrial activities across the countries and has increases the manufacturing plant for oil and gas, chemical, and waters many others. This has result in the increasing demand for the industrial valve that has capability of handling high pressure.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Industrial Valves Market Share Analysis

The industrial valves market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to industrial valves market.

Some of the major players operating in the industrial valves market are:

- Emerson Electric Co. (U.S.)

- Flowserve Corporation (U.S.)

- Crane Company (U.S.)

- IMI (U.K.)

- Velan Inc. (Canada)

- KITZ Corporation (Japan)

- Neway valve (China)

- AVK Holding A/S (Denmark)

- Metso (Finland)

- Spirax Sarco Limited. (U.K.)

- Johnson Controls (Ireland)

- Powell Valves (U.S.)

- Curtiss-Wright. (U.S.)

- Mueller Co. LLC. (U.S.)

- Crane Co., CRANE ChemPharma & Energy Corp (U.S.)

- The Weir Group PLC (U.K.)

- Wärtsilä (Finland)

- Bray International (U.S.)

- Dwyer Instruments LTD (U.S.)

- Watts. (U.S.)

- Bonney Forge Corporation (U.S.)

- NIBCO Inc. (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Asia Pacific Industrial Valves Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Asia Pacific Industrial Valves Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Asia Pacific Industrial Valves Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.