Global Gantry Robot Market

Tamanho do mercado em biliões de dólares

CAGR :

%

USD

3.35 Billion

USD

6.30 Billion

2024

2032

USD

3.35 Billion

USD

6.30 Billion

2024

2032

| 2025 –2032 | |

| USD 3.35 Billion | |

| USD 6.30 Billion | |

|

|

|

|

Segmentação do mercado global de robôs de pórtico, por tipo (robôs de pórtico de 2 eixos, robôs de pórtico de 3 eixos, robôs de pórtico de 4 eixos e robôs de pórtico multieixos), por capacidade de carga útil (até 50 kg, 50–200 kg e acima de 200 kg), aplicação (manuseio de materiais, paletização e despaletização, soldagem e soldagem, montagem, embalagem e outros), usuário final (automotivo, eletrônicos, alimentos e bebidas, aeroespacial, farmacêutico, logística e armazenagem e outros) - tendências do setor e previsão até 2032

Tamanho do mercado de robôs de pórtico

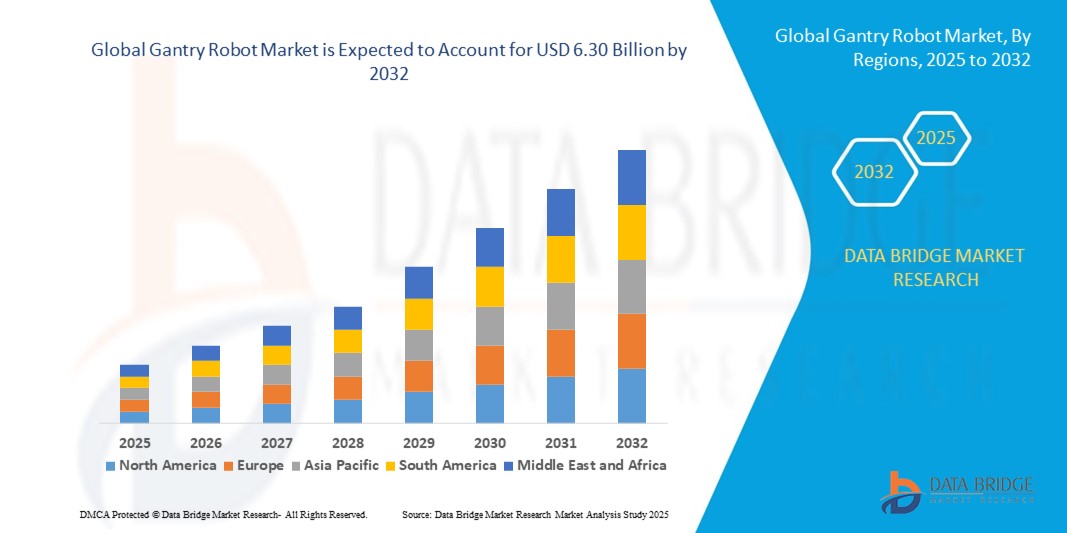

- O tamanho do mercado global de robôs de pórtico foi avaliado em US$ 3,35 bilhões em 2024 e deve atingir US$ 6,30 bilhões até 2032 , com um CAGR de 8,2% durante o período previsto.

- O crescimento do mercado é amplamente impulsionado pela crescente adoção de automação industrial e tecnologias avançadas de fabricação, levando a uma maior demanda por precisão, eficiência e produtividade em vários setores, como automotivo, eletrônico, aeroespacial e logística.

- Além disso, as crescentes exigências industriais por soluções flexíveis, rápidas e robustas para movimentação e montagem de materiais estão consolidando os robôs de pórtico como um sistema de automação preferencial. Esses fatores convergentes estão acelerando a implantação de robôs de pórtico, impulsionando significativamente a expansão do mercado.

Análise de mercado de robôs de pórtico

- Robôs de pórtico são sistemas mecânicos automatizados que se movem ao longo de múltiplos eixos para executar tarefas como movimentação de materiais, montagem, paletização, soldagem e embalagem. Eles oferecem alta precisão, repetibilidade e escalabilidade, tornando-os adequados para operações industriais complexas.

- A crescente demanda por robôs de pórtico é impulsionada principalmente pela necessidade de aumentar a eficiência operacional, reduzir custos de mão de obra e manter a qualidade consistente. Além disso, a integração com IA, IoT e sistemas de fábricas inteligentes está possibilitando operações autônomas e a otimização de processos em tempo real, impulsionando o crescimento do mercado em todas as regiões e setores de uso final.

- A América do Norte dominou o mercado de robôs de pórtico com uma participação de 40,5% em 2024, devido à crescente adoção da automação nas operações de fabricação, logística e depósito

- Espera-se que a Ásia-Pacífico seja a região de crescimento mais rápido no mercado de robôs de pórtico durante o período previsto devido à crescente automação industrial, à rápida urbanização e à expansão de centros de fabricação em países como China, Japão e Índia.

- O segmento de robôs de pórtico de 3 eixos dominou o mercado, com uma participação de mercado de 39% em 2024, devido à sua ampla adoção em automação industrial para tarefas que exigem movimento linear preciso ao longo de três eixos. Sua popularidade advém de um equilíbrio ideal entre funcionalidade, custo-benefício e facilidade de integração em linhas de produção existentes. As indústrias preferem sistemas de 3 eixos para operações de alta velocidade, repetibilidade e compatibilidade com diversas ferramentas e efetores. O crescimento do segmento é ainda sustentado pela forte demanda em processos de movimentação de materiais, embalagem e montagem, onde complexidade e precisão moderadas são suficientes. Os fabricantes também preferem configurações de 3 eixos devido aos seus reduzidos requisitos de manutenção e confiabilidade comprovada.

Escopo do Relatório e Segmentação do Mercado de Robôs de Pórtico

|

Atributos |

Principais insights de mercado sobre robôs de pórtico |

|

Segmentos abrangidos |

|

|

Países abrangidos |

América do Norte

Europa

Ásia-Pacífico

Oriente Médio e África

Ámérica do Sul

|

|

Principais participantes do mercado |

|

|

Oportunidades de mercado |

|

|

Conjuntos de informações de dados de valor agregado |

Além dos insights sobre cenários de mercado, como valor de mercado, taxa de crescimento, segmentação, cobertura geográfica e principais participantes, os relatórios de mercado selecionados pela Data Bridge Market Research também incluem análises aprofundadas de especialistas, produção e capacidade de empresas representadas geograficamente, layouts de rede de distribuidores e parceiros, análises detalhadas e atualizadas de tendências de preços e análises de déficit da cadeia de suprimentos e demanda. |

Tendências do mercado de robôs de pórtico

Aumento da escassez de mão de obra

- A crescente escassez de mão de obra nos setores de manufatura, logística e processamento está impulsionando significativamente a demanda por robôs de pórtico. À medida que as indústrias enfrentam a escassez de mão de obra, especialmente em tarefas repetitivas, perigosas e que exigem precisão, os robôs de pórtico estão emergindo como uma solução confiável para manter a produtividade e a eficiência operacional.

- Por exemplo, a ABB e o Grupo Güdel desenvolveram sistemas avançados de robôs de pórtico que estão sendo implantados em instalações de fabricação automotiva, onde a escassez de mão de obra e a crescente demanda por qualidade consistente estão impulsionando a adoção da automação. Esses sistemas ajudam os fabricantes a cumprir os prazos de produção, reduzindo a dependência de intervenção manual.

- A capacidade estrutural dos robôs de pórtico para realizar tarefas pesadas de movimentação de materiais, paletização e embalagem os torna essenciais em setores como automotivo, eletrônico e e-commerce. Em regiões com graves restrições de mão de obra, esses robôs preenchem a lacuna de qualificação, garantindo velocidade, precisão e segurança nas linhas de produção.

- O crescimento global das atividades de comércio eletrônico e logística aumentou a dependência de sistemas automatizados, visto que armazéns e centros de distribuição enfrentam restrições significativas de mão de obra. Robôs de pórtico reduzem os atrasos nas entregas, executando tarefas repetitivas de triagem e manuseio com maior eficiência do que o trabalho manual.

- Além disso, o envelhecimento populacional em regiões desenvolvidas, como Europa e Japão, está intensificando a escassez de mão de obra nos setores industriais, acelerando a adoção de alternativas automatizadas. Robôs de pórtico estão se tornando investimentos estratégicos para mitigar a lacuna na força de trabalho e sustentar a competitividade nas cadeias de suprimentos globais.

- De modo geral, a crescente escassez de mão de obra está posicionando os robôs de pórtico como ferramentas indispensáveis para a resiliência industrial. Essa tendência reflete uma mudança estrutural na forma como as empresas veem a automação — não apenas como uma forma de reduzir custos, mas como uma necessidade de longo prazo para enfrentar os desafios da força de trabalho e garantir uma produção consistente.

Dinâmica do mercado de robôs de pórtico

Motorista

Aumento da demanda por automação em vários setores

- A crescente demanda por automação em setores como manufatura, automotivo, eletrônicos, logística e processamento de alimentos é um dos principais impulsionadores do mercado de robôs de pórtico. As empresas estão recorrendo a soluções automatizadas para lidar com tarefas de precisão, reduzir custos operacionais e aumentar a produtividade em mercados globais competitivos.

- Por exemplo, a FANUC Corporation expandiu seu portfólio de robôs de pórtico para atender linhas de montagem automotivas de alto volume, onde o manuseio e a soldagem automatizados se tornaram essenciais devido ao aumento dos volumes de produção global. Essas implementações destacam como a automação é vital para alcançar eficiência de custos e consistência em todos os setores.

- A busca pela automação é ainda mais reforçada pela necessidade de minimizar o erro humano, aprimorar a qualidade e manter ambientes de trabalho seguros. Os robôs de pórtico se destacam em tarefas repetitivas e pesadas, como alimentação de máquinas, paletização, embalagem e transferência de materiais, atendendo aos requisitos de precisão e velocidade da indústria.

- Indústrias que enfrentam padrões de demanda flutuantes e ciclos de vida de produtos mais curtos contam com robôs de pórtico para maior flexibilidade. Sua estrutura modular permite a integração com máquinas CNC, transportadores e sistemas de armazenamento automatizados, tornando-os componentes valiosos de iniciativas da Indústria 4.0 e fábricas inteligentes.

- Em conclusão, a rápida mudança em direção à automação industrial em diversos setores apoia fortemente a adoção de robôs de pórtico. Este fator ilustra como as empresas dependem cada vez mais de soluções robóticas para manter a eficiência, a competitividade e a resiliência diante dos desafios operacionais.

Restrição/Desafio

Necessidade de conhecimento técnico

- Um grande desafio no mercado de robôs de pórtico é o alto nível de expertise técnica necessária para implantação, operação e manutenção desses sistemas. Ao contrário da automação convencional, os robôs de pórtico exigem profissionais qualificados para programação, calibração e integração aos fluxos de trabalho existentes, o que cria barreiras para adoção.

- Por exemplo, a KUKA e o Grupo Güdel enfatizam o treinamento e o suporte de serviço para suas instalações de robôs de pórtico, visto que muitas empresas clientes enfrentam dificuldades para desenvolver expertise interna. A falta de operadores e engenheiros qualificados frequentemente atrasa os cronogramas dos projetos e aumenta os custos gerais de implantação para os usuários finais.

- A complexidade da integração de robôs de pórtico com linhas de produção, sistemas de transporte ou plataformas de fábricas inteligentes aumenta a carga técnica. Qualquer configuração incorreta ou falta de conhecimento especializado pode levar a ineficiências, tempo de inatividade e aumento da necessidade de manutenção ao longo do tempo.

- Além disso, as pequenas e médias empresas (PMEs) frequentemente têm dificuldade em investir em treinamento especializado de mão de obra ou em reter técnicos qualificados, criando dependência de prestadores de serviços terceirizados. Essa dependência aumenta os custos e reduz o controle sobre as estratégias de manutenção de longo prazo.

- Como resultado, a necessidade de conhecimento técnico continua a dificultar a adoção generalizada de robôs de pórtico, especialmente em mercados dominados por PMEs. Enfrentar esse desafio exigirá interfaces de programação simplificadas, maior automação na configuração e iniciativas mais amplas de treinamento da força de trabalho para garantir a adoção sustentável em todos os setores.

Escopo de mercado de robôs de pórtico

O mercado é segmentado com base no tipo, capacidade de carga útil, aplicação e usuário final.

- Por tipo

Com base no tipo, o mercado de robôs de pórtico é segmentado em robôs de pórtico de 2 eixos, robôs de pórtico de 3 eixos, robôs de pórtico de 4 eixos e robôs de pórtico multieixos. O segmento de robôs de pórtico de 3 eixos dominou a maior fatia de receita de mercado de 39% em 2024, impulsionado por sua ampla adoção em automação industrial para tarefas que exigem movimento linear preciso ao longo de três eixos. Sua popularidade decorre de um equilíbrio ideal entre funcionalidade, custo-benefício e facilidade de integração em linhas de produção existentes. As indústrias preferem sistemas de 3 eixos para operações de alta velocidade, repetibilidade e compatibilidade com várias ferramentas e efetores finais. O crescimento do segmento é ainda apoiado pela forte demanda em processos de manuseio de materiais, embalagem e montagem, onde complexidade e precisão moderadas são suficientes. Os fabricantes também preferem configurações de 3 eixos devido aos seus requisitos de manutenção reduzidos e confiabilidade comprovada.

Prevê-se que o segmento de Robôs de Pórtico Multieixos apresentará a maior taxa de crescimento entre 2025 e 2032, impulsionado pelos crescentes requisitos de automação em processos de fabricação complexos. Os sistemas multieixos oferecem maior flexibilidade, permitindo movimentos multidirecionais simultâneos para tarefas complexas de montagem, soldagem e produção eletrônica. A crescente adoção das práticas da Indústria 4.0 e da robótica colaborativa está incentivando os fabricantes a implantar robôs de pórtico multieixos para maior eficiência e precisão. Sua capacidade de lidar com operações diversas, ao mesmo tempo em que reduz os custos de mão de obra, os torna altamente atraentes nos setores automotivo, aeroespacial e eletrônico.

- Por capacidade de carga útil

Com base na capacidade de carga útil, o mercado de robôs de pórtico é segmentado em até 50 kg, 50–200 kg e acima de 200 kg. O segmento de 50–200 kg dominou o mercado em 2024, impulsionado pela versatilidade de robôs de carga útil de médio porte em diversas aplicações industriais. Este segmento oferece uma combinação ideal de capacidade de manuseio de carga e velocidade operacional, tornando-o adequado para operações de manuseio de materiais, paletização e montagem. As indústrias dependem cada vez mais de robôs de pórtico de carga útil média para operações de serviço moderado a pesado, sem exigir o alto investimento associado a sistemas de carga útil ultrapesada. O segmento se beneficia da demanda consistente em setores como automotivo, eletrônico e alimentos e bebidas, onde a eficiência e a precisão da produção são essenciais.

Espera-se que o segmento de cargas úteis acima de 200 kg apresente o CAGR mais rápido entre 2025 e 2032, impulsionado pela crescente automação nas indústrias pesadas e logística. Robôs com maior capacidade de carga útil são essenciais para o manuseio de componentes volumosos em montagens automotivas, fabricação aeroespacial e operações de embalagem em larga escala. Os avanços tecnológicos que permitem robôs de pórtico de alta capacidade, robustos, duráveis e precisos, estão incentivando os fabricantes a adotar essas soluções. A necessidade de maior produtividade, redução do trabalho manual e maior segurança no local de trabalho está impulsionando ainda mais a demanda por sistemas de cargas úteis acima de 200 kg.

- Por aplicação

Com base na aplicação, o mercado de robôs de pórtico é segmentado em movimentação de materiais, paletização e despaletização, soldagem e soldagem, montagem, embalagem e outros. O segmento de movimentação de materiais dominou o mercado em 2024, impulsionado por seu amplo uso em diversas indústrias para movimentar matérias-primas, componentes e produtos acabados com eficiência. Os robôs de pórtico para movimentação de materiais melhoram a automação do fluxo de trabalho, reduzem a intervenção humana e aumentam a segurança no local de trabalho, tornando-os essenciais para instalações de produção modernas. Sua adaptabilidade a diversas cargas úteis e a integração com sistemas de transporte e soluções de gerenciamento de armazéns contribuem para a forte demanda. As indústrias se beneficiam de tempos de ciclo reduzidos, maior produtividade e posicionamento preciso de mercadorias, reforçando a posição de liderança do segmento.

Prevê-se que o segmento de soldagem e brasagem apresentará a maior taxa de crescimento entre 2025 e 2032, impulsionado pela crescente adoção na indústria automotiva, eletrônica e de equipamentos pesados. Robôs de pórtico em aplicações de soldagem e brasagem proporcionam alta precisão, qualidade de solda consistente e velocidades de produção aceleradas. A integração de sensores avançados e sistemas de controle adaptativos aumenta a eficiência e reduz o desperdício de material. Os crescentes investimentos em processos automatizados de fabricação, juntamente com a necessidade de soldas de alta qualidade e repetíveis, estão impulsionando a rápida implantação de robôs de pórtico nessas operações.

- Por usuário final

Com base no usuário final, o mercado de robôs de pórtico é segmentado em automotivo, eletrônicos, alimentos e bebidas, aeroespacial, farmacêutico, logística e armazenagem, entre outros. O segmento automotivo dominou o mercado em 2024, impulsionado pelo amplo uso de robôs de pórtico em operações de montagem, movimentação de materiais e soldagem. Os fabricantes automotivos estão cada vez mais implantando robôs de pórtico para aumentar a velocidade de produção, garantir qualidade consistente e atender às demandas de fabricação em larga escala. O segmento se beneficia de altos investimentos em automação, forte demanda por veículos elétricos e da necessidade de manuseio preciso de componentes pesados, como motores e chassis.

Espera-se que o segmento de eletrônicos apresente o CAGR mais rápido entre 2025 e 2032, impulsionado pelo crescimento da produção de eletrônicos de consumo, semicondutores e componentes de alta precisão. Robôs de pórtico na fabricação de eletrônicos oferecem soluções compactas, precisas e automatizadas para processos de montagem, soldagem e testes. A crescente demanda por dispositivos miniaturizados, maior precisão de produção e tempos de resposta mais curtos está impulsionando a rápida adoção da robótica de pórtico neste setor.

Análise regional do mercado de robôs de pórtico

- A América do Norte dominou o mercado de robôs de pórtico com a maior participação de receita de 40,5% em 2024, impulsionada pela crescente adoção da automação nas operações de fabricação, logística e depósito

- As empresas da região estão investindo cada vez mais em robótica para aumentar a produtividade, reduzir custos de mão de obra e manter alta precisão na produção

- A ampla adoção é ainda apoiada por uma infraestrutura tecnológica avançada, elevadas capacidades de investimento de capital e um forte foco na implementação da Indústria 4.0.

Visão do mercado de robôs de pórtico dos EUA

O mercado de robôs de pórtico dos EUA conquistou a maior fatia da receita da América do Norte em 2024, impulsionado pelas rápidas tendências de automação e modernização industrial. As empresas estão cada vez mais implantando robôs de pórtico para aprimorar a precisão da fabricação, melhorar a eficiência operacional e dar suporte a linhas de produção de alto volume. A forte presença dos setores automotivo, eletrônico e de logística, aliada à crescente demanda por soluções de movimentação de materiais baseadas em robótica, continua impulsionando o crescimento do mercado. Além disso, a integração de robôs com sistemas de manufatura habilitados para IoT e configurações de armazéns inteligentes está expandindo significativamente seu escopo de aplicação.

Visão geral do mercado de robôs de pórtico na Europa

O mercado europeu de robôs de pórtico deverá crescer a um CAGR substancial ao longo do período previsto, impulsionado principalmente por padrões rigorosos de eficiência, aumento da automação industrial e crescente adoção da robótica na manufatura e armazenagem. Países como Alemanha, França e Itália estão testemunhando uma crescente implantação de robôs de pórtico na fabricação automotiva, aeroespacial e eletrônica. As empresas europeias estão se concentrando em precisão, eficiência energética e integração de automação, o que está fomentando uma maior demanda por robôs de pórtico em instalações de produção e operações logísticas.

Visão geral do mercado de robôs de pórtico do Reino Unido

O mercado de robôs de pórtico do Reino Unido deverá crescer a um CAGR considerável durante o período previsto, impulsionado pelo aumento da automação nos setores de manufatura e logística. As empresas estão adotando robôs de pórtico para melhorar a produtividade, garantir a qualidade consistente dos produtos e otimizar a utilização do espaço em armazéns. O crescimento do mercado é ainda apoiado por iniciativas governamentais que promovem as práticas da Indústria 4.0 e a adoção da robótica em PMEs e unidades de manufatura de grande porte, além do aumento dos investimentos em infraestrutura de fábricas inteligentes.

Visão do mercado de robôs de pórtico na Alemanha

Espera-se que o mercado alemão de robôs de pórtico se expanda a um CAGR considerável durante o período previsto, impulsionado por fortes práticas de automação industrial e uma alta demanda por engenharia de precisão. Os setores automotivo, eletrônico e aeroespacial da Alemanha estão cada vez mais utilizando robôs de pórtico para aumentar a eficiência operacional e manter vantagens competitivas. A ênfase em inovação, manufatura inteligente e integração com sistemas de fábrica digitais está impulsionando a adoção, enquanto soluções focadas em sustentabilidade e robótica com eficiência energética são cada vez mais favorecidas em aplicações comerciais e industriais.

Visão do mercado de robôs de pórtico da Ásia-Pacífico

O mercado de robôs de pórtico da Ásia-Pacífico deverá crescer com a CAGR mais rápida durante o período previsto de 2025 a 2032, impulsionado pela crescente automação industrial, rápida urbanização e expansão de polos de manufatura em países como China, Japão e Índia. O crescente foco da região em fábricas inteligentes, iniciativas governamentais que promovem a adoção da robótica e a crescente disponibilidade de soluções robóticas com boa relação custo-benefício são fatores-chave de crescimento. Além disso, o papel da APAC como polo de produção de componentes e sistemas robóticos está melhorando a acessibilidade e o preço acessível, impulsionando a adoção de robôs de pórtico em operações de manufatura, logística e montagem.

Visão geral do mercado de robôs de pórtico do Japão

O mercado japonês de robôs de pórtico está ganhando impulso devido ao avançado setor de manufatura do país, à ênfase em automação e à demanda por robótica de alta precisão. Empresas japonesas estão adotando robôs de pórtico para processos de movimentação de materiais, montagem e embalagem, visando melhorar a produtividade e a qualidade. A integração de robôs com sistemas de produção habilitados para IoT e iniciativas de fábricas inteligentes está acelerando a adoção. Além disso, o envelhecimento da força de trabalho japonesa está incentivando a automação para garantir a continuidade operacional e manter a eficiência da produção em todos os setores industriais.

Visão do mercado de robôs de pórtico da China

O mercado chinês de robôs de pórtico foi responsável pela maior fatia da receita de mercado na região Ásia-Pacífico em 2024, devido à robusta base industrial do país, à rápida urbanização e ao apoio governamental à automação e à manufatura inteligente. A adoção de robôs de pórtico é impulsionada pelas necessidades de produção em alto volume nos setores automotivo, eletrônico e de logística. A busca por fábricas inteligentes, a capacidade de fabricação de robótica doméstica e a disponibilidade de soluções econômicas impulsionam ainda mais o mercado. Fortes investimentos industriais e a rápida integração de tecnologias de automação em todas as linhas de produção estão consolidando a posição da China como um mercado-chave para robôs de pórtico.

Participação no mercado de robôs de pórtico

A indústria de robôs de pórtico é liderada principalmente por empresas bem estabelecidas, incluindo:

- KUKA AG (Alemanha)

- ABB Ltd. (Suíça)

- Yaskawa Electric Corporation (Japão)

- FANUC Corporation (Japão)

- Siemens AG (Alemanha)

- Parker Hannifin Corporation (EUA)

- Thomson Industries, Inc. (EUA)

- Schneider Electric SE (França)

- Zollern GmbH & Co. KG (Alemanha)

- Robôs Industriais IAI (Japão)

- Festo AG & Co. KG (Alemanha)

- Bosch Rexroth AG (Alemanha)

- Bürobotec GmbH (Alemanha)

Últimos desenvolvimentos no mercado global de robôs de pórtico

- Em outubro de 2023, a Neuromeka, empresa líder em robótica colaborativa, e a KEBA, fornecedora global de soluções de robótica e automação industrial, firmaram um Memorando de Entendimento (MOU) para o desenvolvimento conjunto de robôs industriais avançados. Espera-se que essa parceria estratégica acelere a inovação no mercado de robôs de pórtico, combinando sua expertise em automação e robótica colaborativa. A colaboração visa aprimorar a flexibilidade, a precisão e a eficiência dos sistemas robóticos industriais, atendendo assim à crescente demanda por soluções para fábricas inteligentes e automação de alto desempenho em todos os setores da indústria.

- Em 2023, a ABB apresentou o IRB 6700, um robô de pórtico de alto desempenho projetado especificamente para aplicações de alta resistência nas indústrias automotiva e aeroespacial. O design robusto do robô, aliado à integração de inteligência artificial (IA) e recursos de aprendizado de máquina (ML), aprimora a tomada de decisões autônoma e a eficiência operacional. Este lançamento fortalece a posição da ABB no mercado de robôs de pórtico e atende a indústrias que exigem alta precisão, manuseio de cargas pesadas e ciclos de produção otimizados, impulsionando o crescimento geral do mercado.

- Em julho de 2022, a FANUC lançou uma linha atualizada de robôs de pórtico com capacidade de carga útil aprimorada e alcance estendido para aplicações de montagem e movimentação de materiais. Essas atualizações atendem a setores como automotivo, eletrônico e logística, onde alta produtividade e precisão são essenciais. Ao melhorar a flexibilidade operacional e reduzir os tempos de ciclo, espera-se que os robôs de pórtico aprimorados da FANUC impulsionem uma maior adoção em setores industriais existentes e emergentes.

- Em maio de 2021, a Yaskawa Motoman apresentou um sistema robótico de pórtico modular com eixos escaláveis e opções de carga útil, visando otimizar a eficiência da produção na indústria automotiva e eletrônica. O design modular permite que os fabricantes personalizem as configurações robóticas com base nos requisitos específicos da aplicação, aprimorando a automação do fluxo de trabalho e reduzindo os gastos de capital. Esse desenvolvimento contribuiu para expandir a versatilidade e a penetração de mercado dos robôs de pórtico, especialmente em regiões com forte investimento em iniciativas da Indústria 4.0.

- Em fevereiro de 2020, a Bosch Rexroth, importante fornecedora de soluções de automação, lançou um novo portal de e-commerce para oferecer acesso simplificado a uma ampla gama de componentes hidráulicos e de automação industrial da Rexroth. Essa iniciativa aumenta a conveniência e a eficiência nas compras, permitindo que os fabricantes obtenham rapidamente componentes para robôs de pórtico e produtos de automação relacionados. O portal facilita a implantação mais rápida de soluções de automação industrial, apoiando a expansão da adoção de robôs de pórtico em operações de manufatura e logística.

SKU-

Obtenha acesso online ao relatório sobre a primeira nuvem de inteligência de mercado do mundo

- Painel interativo de análise de dados

- Painel de análise da empresa para oportunidades de elevado potencial de crescimento

- Acesso de analista de pesquisa para personalização e customização. consultas

- Análise da concorrência com painel interativo

- Últimas notícias, atualizações e atualizações Análise de tendências

- Aproveite o poder da análise de benchmark para um rastreio abrangente da concorrência

Metodologia de Investigação

A recolha de dados e a análise do ano base são feitas através de módulos de recolha de dados com amostras grandes. A etapa inclui a obtenção de informações de mercado ou dados relacionados através de diversas fontes e estratégias. Inclui examinar e planear antecipadamente todos os dados adquiridos no passado. Da mesma forma, envolve o exame de inconsistências de informação observadas em diferentes fontes de informação. Os dados de mercado são analisados e estimados utilizando modelos estatísticos e coerentes de mercado. Além disso, a análise da quota de mercado e a análise das principais tendências são os principais fatores de sucesso no relatório de mercado. Para saber mais, solicite uma chamada de analista ou abra a sua consulta.

A principal metodologia de investigação utilizada pela equipa de investigação do DBMR é a triangulação de dados que envolve a mineração de dados, a análise do impacto das variáveis de dados no mercado e a validação primária (especialista do setor). Os modelos de dados incluem grelha de posicionamento de fornecedores, análise da linha de tempo do mercado, visão geral e guia de mercado, grelha de posicionamento da empresa, análise de patentes, análise de preços, análise da quota de mercado da empresa, normas de medição, análise global versus regional e de participação dos fornecedores. Para saber mais sobre a metodologia de investigação, faça uma consulta para falar com os nossos especialistas do setor.

Personalização disponível

A Data Bridge Market Research é líder em investigação formativa avançada. Orgulhamo-nos de servir os nossos clientes novos e existentes com dados e análises que correspondem e atendem aos seus objetivos. O relatório pode ser personalizado para incluir análise de tendências de preços de marcas-alvo, compreensão do mercado para países adicionais (solicite a lista de países), dados de resultados de ensaios clínicos, revisão de literatura, mercado remodelado e análise de base de produtos . A análise de mercado dos concorrentes-alvo pode ser analisada desde análises baseadas em tecnologia até estratégias de carteira de mercado. Podemos adicionar quantos concorrentes necessitar de dados no formato e estilo de dados que procura. A nossa equipa de analistas também pode fornecer dados em tabelas dinâmicas de ficheiros Excel em bruto (livro de factos) ou pode ajudá-lo a criar apresentações a partir dos conjuntos de dados disponíveis no relatório.