Wire Arc Additive Manufacturing (WAAM) ist ein fortschrittliches additives Fertigungsverfahren, bei dem ein Lichtbogen als Wärmequelle zum Schmelzen von Metalldrähten verwendet wird. Anschließend werden diese schichtweise aufgetragen, um dreidimensionale Bauteile zu erzeugen. Dieser Prozess ähnelt dem herkömmlichen Schweißen, wird jedoch durch CAD- und CAM-Software (Computer-Aided Design) gesteuert und ermöglicht so die präzise Konstruktion komplexer und großformatiger Metallteile. WAAM wird in verschiedenen Branchen eingesetzt, darunter der Luft- und Raumfahrt, der Automobilindustrie und der Schifffahrt, da es die effiziente und kostengünstige Herstellung hochfester, kundenspezifischer Metallstrukturen ermöglicht.

Vollständigen Bericht abrufen unter https://www.databridgemarketresearch.com/reports/north-america-europe-and-asia-pacific-wire-arc-additive-manufacturing-market

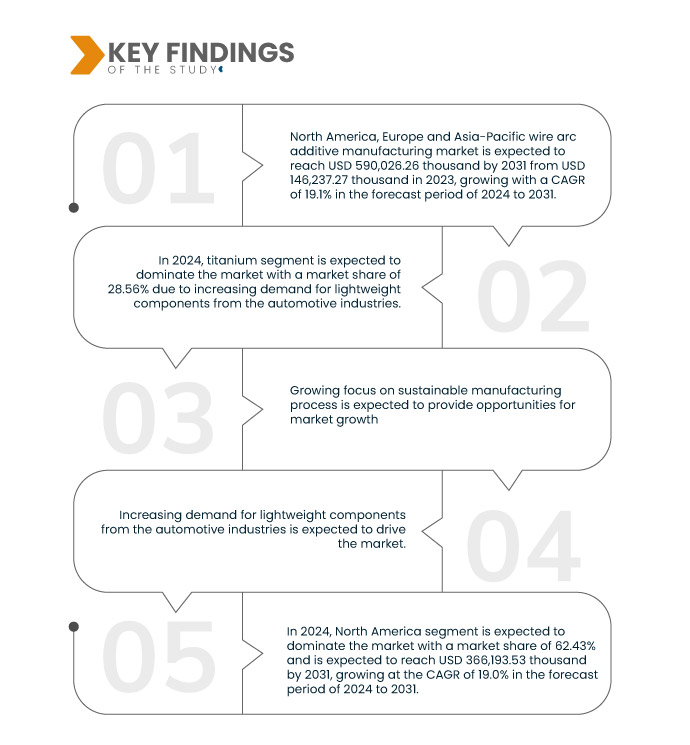

Data Bridge Market Research analysiert den Markt für additive Drahtlichtbogenfertigung in Nordamerika, Europa und im asiatisch-pazifischen Raum. Er soll von 146.237.270 USD im Jahr 2023 auf 590.026.260 USD im Jahr 2031 anwachsen und im Prognosezeitraum von 2024 bis 2031 eine durchschnittliche jährliche Wachstumsrate (CAGR) von 19,1 % erreichen. Die steigende Nachfrage nach Leichtbauteilen aus der Automobilindustrie treibt das Marktwachstum voran.

Wichtigste Ergebnisse der Studie

Vorteile der additiven Fertigung in der Luft- und Raumfahrtindustrie

Wire Arc Additive Manufacturing (WAAM) erfreut sich in der Luft- und Raumfahrtindustrie zunehmender Beliebtheit, da es die effiziente und gewichtsreduzierte Herstellung komplexer Hochleistungskomponenten ermöglicht. Durch den Einsatz eines Lichtbogens zum Schmelzen von Metalldrähten und zum Schichtaufbau ermöglicht WAAM komplexe Geometrien und individuelle Designs, die mit herkömmlichen Methoden nicht realisierbar sind. Diese Technologie ermöglicht Rapid Prototyping mit kürzeren Durchlaufzeiten und Kostenvorteilen bei kleinen Stückzahlen oder komplexen Bauteilen durch reduzierten Materialabfall und reduzierte Bearbeitung. WAAM unterstützt Materialien wie Aluminium , Titan und Nickellegierungen, die den Leistungsanforderungen der Luft- und Raumfahrt entsprechen. Kontinuierliche Verbesserungen von WAAM erweitern dessen Möglichkeiten und machen es zu einer bahnbrechenden Technologie für effizientere, leichtere und nachhaltigere Flugzeugkonstruktionen.

Berichtsumfang und Marktsegmentierung

Berichtsmetrik

|

Details

|

Prognosezeitraum

|

2024 bis 2031

|

Basisjahr

|

2023

|

Historische Jahre

|

2022 (Anpassbar auf 2016–2021)

|

Quantitative Einheiten

|

Umsatz in Tausend USD

|

Abgedeckte Segmente

|

Metall ( Titan , Stahl, Edelstahl , Nickel, Aluminium und andere), Anwendung (Luft- und Raumfahrt, Gesundheitswesen, Automobilindustrie, industrielle Fertigung, Militär und Verteidigung, Architektur und andere)

|

Abgedeckte Länder

|

USA, Kanada, Mexiko, Deutschland, Italien, Großbritannien, Frankreich, Spanien, Türkei, Russland, Schweiz, Belgien, Niederlande, Restliches Europa, China, Japan, Südkorea, Indien, Singapur, Indonesien, Thailand, Philippinen, Australien und Neuseeland, Malaysia, Restlicher Asien-Pazifik-Raum

|

Abgedeckte Marktteilnehmer

|

YAMAZAKI MAZAK CORPORATION (Japan), WAAM3D LIMITED (England), Fraunhofer-Gesellschaft e. V., München (Deutschland), RAMLAB (Niederlande), AML3D (Australien) und Vallourec (Frankreich) unter anderem

|

Im Bericht behandelte Datenpunkte

|

Zusätzlich zu den Einblicken in Marktszenarien wie Marktwert, Wachstumsrate, Segmentierung, geografische Abdeckung und wichtige Akteure enthalten die von Data Bridge Market Research kuratierten Marktberichte auch ausführliche Expertenanalysen, geografisch dargestellte Produktion und Kapazität nach Unternehmen, Netzwerklayouts von Distributoren und Partnern, detaillierte und aktuelle Preistrendanalysen und Defizitanalysen der Lieferkette und Nachfrage.

|

Segmentanalyse:

Der Markt für additive Drahtlichtbogenfertigung in Nordamerika, Europa und im asiatisch-pazifischen Raum ist in zwei wichtige Segmente unterteilt, die auf Metall und Anwendung basieren.

- Auf der Grundlage von Metall ist der Markt in Titan, Stahl, Edelstahl, Nickel, Aluminium und andere segmentiert

Im Jahr 2024 wird das Titansegment voraussichtlich den Markt für additive Drahtlichtbogenfertigung dominieren

Im Jahr 2024 wird das Titansegment voraussichtlich den Markt für additive Drahtlichtbogenfertigung mit einem Marktanteil von 28,56 % dominieren, und zwar aufgrund seines außergewöhnlichen Festigkeits-Gewichts-Verhältnisses, seiner Korrosionsbeständigkeit und seiner hohen Leistung bei anspruchsvollen Anwendungen .

- Auf der Grundlage der Anwendung ist der Markt in Luft- und Raumfahrt, Gesundheitswesen, Automobilindustrie, industrielle Fertigung, Militär und Verteidigung, Architektur und andere segmentiert

Im Jahr 2024 wird das Luft- und Raumfahrtsegment voraussichtlich den Markt für Drahtlichtbogen-Additive Fertigung dominieren

Im Jahr 2024 wird das Segment Luft- und Raumfahrt aufgrund seines Bedarfs an leistungsstarken, leichten und komplexen Komponenten voraussichtlich den Markt für additive Drahtlichtbogenfertigung mit einem Marktanteil von 29,50 % dominieren.

Hauptakteure

Data Bridge Market Research analysiert Vallourec (Frankreich), Fraunhofer-Gesellschaft e. V., München (Deutschland), YAMAZAKI MAZAK CORPORATION (Japan), AML3D (Australien) und RAMLAB (Niederlande) als die wichtigsten Akteure auf dem Markt.

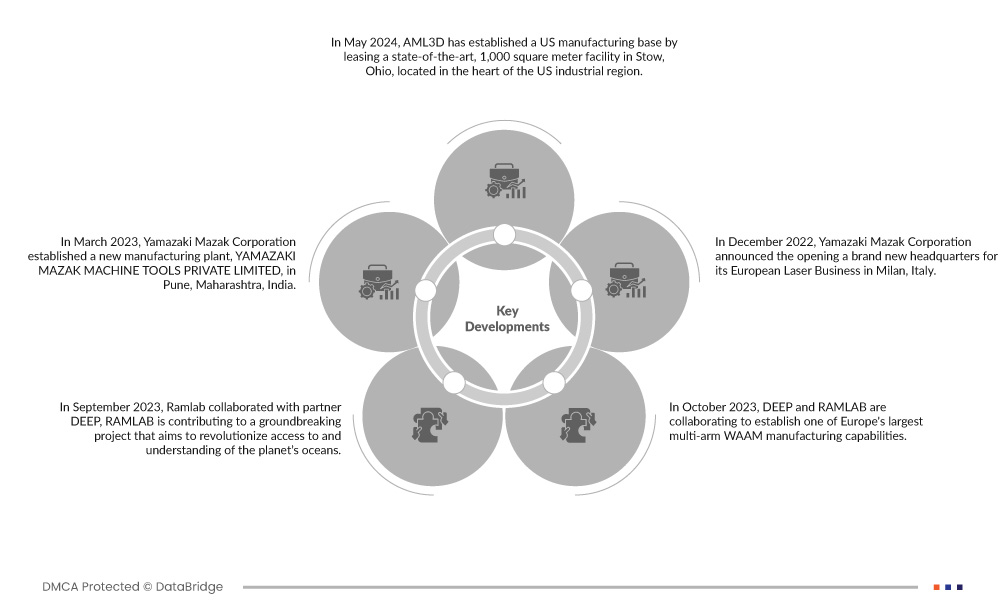

Marktentwicklung

- Im Mai 2024 hat AML3D einen US-Produktionsstandort durch die Anmietung einer hochmodernen, 1.000 Quadratmeter großen Anlage in Stow, Ohio, im Herzen der US-Industrieregion, errichtet. Diese moderne, vorkonfigurierte Anlage dient als Produktions-, Vertriebs- und Unternehmenszentrum und bietet AML3D eine betriebsbereite Basis zur landesweiten Kundenbetreuung. Gelegen in einem Industriegebiet mit Zugang zu moderner Verkehrsinfrastruktur ist dieser neue Standort ein entscheidender Bestandteil der Strategie von AML3D, die große und wachsende Nachfrage in den USA, insbesondere im US-Verteidigungssektor, zu decken.

- Im März 2023 eröffnete die Yamazaki Mazak Corporation in Pune, Maharashtra, Indien, ein neues Produktionswerk: YAMAZAKI MAZAK MACHINE TOOLS PRIVATE LIMITED. Dieses Werk wird ein neu entwickeltes, in Japan für den indischen Markt konzipiertes vertikales Bearbeitungszentrum produzieren. Mit dieser Erweiterung verfügt Yamazaki Mazak nun über elf Produktionsstandorte – fünf in Japan und sechs im Ausland. Diese Expansion unterstreicht das Engagement des Unternehmens, die globale Fertigungsindustrie durch lokale Produktion und Serviceunterstützung voranzutreiben.

- Im September 2023 kooperierte Ramlab mit seinem Partner DEEP. RAMLAB trägt zu einem bahnbrechenden Projekt bei, das den Zugang zu den Ozeanen unseres Planeten und deren Verständnis revolutionieren soll. DEEP stellt das DEEP Sentinel-System vor, eine skalierbare, modulare und autonome Unterwasserstation, die für den Einsatz in bis zu 200 Metern Tiefe konzipiert ist. Dieses innovative System, das hauptsächlich mittels Wire Arc Additive Manufacturing (WAAM) und der MaxQ Monitoring & Control-Technologie von RAMLAB hergestellt wird, wird den Zugang zu den Kontinentalschelfen und der Epipelagic Zone (Sonnenlichtzone), die über 90 % des Meereslebens beherbergt, deutlich verbessern.

- Im Oktober 2023 kooperieren DEEP und RAMLAB, um eine der größten Produktionskapazitäten für Mehrarm-WAAMs in Europa aufzubauen. Ziel dieser Initiative ist die Herstellung von begehbaren Druckbehältern. Dank der Partnerschaft mit RAMLAB ist das Unternehmen bereit, das volle Potenzial der Mehrarm-WAAM-Technologie auszuschöpfen und diesen wichtigen Meilenstein zu erreichen.

- Im Dezember 2022 gab die Yamazaki Mazak Corporation die Eröffnung eines brandneuen Hauptsitzes für ihr europäisches Lasergeschäft in Mailand, Italien, bekannt. Im Laufe seiner langen Geschichte hat das Unternehmen weltweit zehn Produktionsstätten und mehrere Vertriebsniederlassungen errichtet, davon 14 in Europa. Diese Entwicklung wird dem Unternehmen helfen, sein Geschäft in Europa auszubauen.

Regionale Analyse

Geografisch ist der Markt in die USA, Kanada, Mexiko, Deutschland, Italien, Großbritannien, Frankreich, Spanien, Türkei, Russland, Schweiz, Belgien, Niederlande, übriges Europa, China, Japan, Südkorea, Indien, Singapur, Indonesien, Thailand, Philippinen, Australien und Neuseeland, Malaysia sowie den Rest des asiatisch-pazifischen Raums unterteilt.

Laut Marktforschungsanalyse von Data Bridge :

Nordamerika ist die dominierende Region im nordamerikanischen, europäischen und asiatisch-pazifischen Markt für additive Drahtlichtbogenfertigung

Das nordamerikanische Segment dominiert den Markt für additive Drahtlichtbogenfertigung aufgrund seiner starken industriellen Basis, der fortschrittlichen technologischen Infrastruktur und erheblicher Investitionen in Forschung und Entwicklung. Die Region ist Sitz zahlreicher führender Unternehmen der Luft- und Raumfahrt, der Automobilindustrie und der Verteidigungsindustrie, die innovative Fertigungstechnologien frühzeitig einsetzen.

Der asiatisch-pazifische Raum wird voraussichtlich die am schnellsten wachsende Region im nordamerikanischen, europäischen und asiatisch-pazifischen Markt für additive Drahtlichtbogenfertigung sein.

Der asiatisch-pazifische Raum dürfte aufgrund der Präsenz großer Fertigungszentren und steigender staatlicher Förderung der additiven Fertigung die am schnellsten wachsende Region sein.

Für detailliertere Informationen zum Marktbericht zur additiven Drahtlichtbogenfertigung in Nordamerika, Europa und im asiatisch-pazifischen Raum klicken Sie hier – https://www.databridgemarketresearch.com/reports/north-america-europe-and-asia-pacific-wire-arc-additive-manufacturing-market