Global Capacitive Ceramic Pressure Sensor Market

Market Size in USD Billion

CAGR :

%

USD

1.08 Billion

USD

2.29 Billion

2024

2032

USD

1.08 Billion

USD

2.29 Billion

2024

2032

| 2025 –2032 | |

| USD 1.08 Billion | |

| USD 2.29 Billion | |

|

|

|

|

Capacitive Ceramic Pressure Sensor Market Size

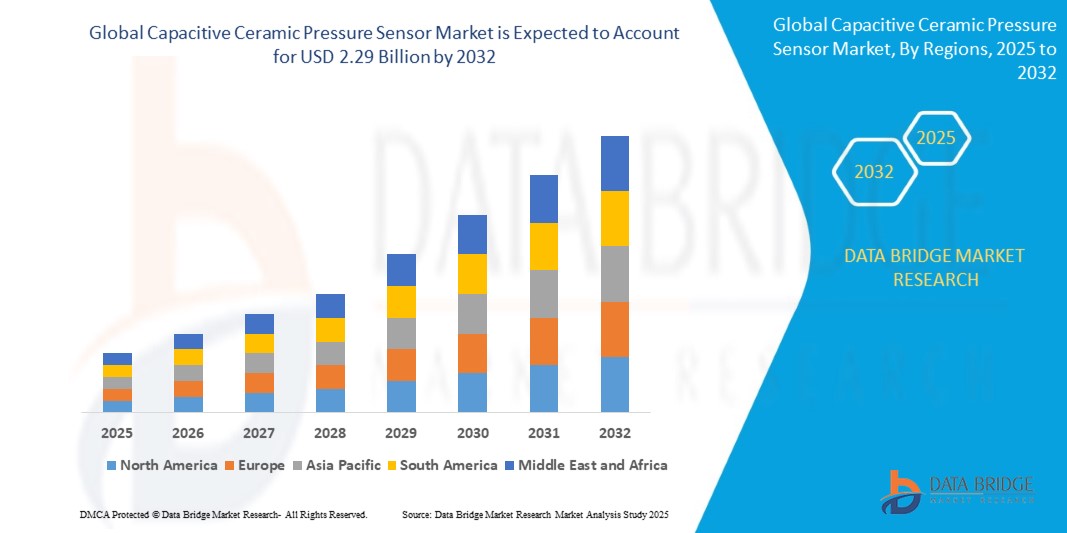

- The Global Capacitive Ceramic Pressure Sensor Market was valued at USD 1.08 billion in 2025 and is projected to reach USD 2.29 billion by 2032, growing at a strong CAGR of 7.82% during the forecast period.

- Growth is driven by rising demand for robust, corrosion-resistant, and cost-effective pressure sensing solutions across automotive, industrial automation, and medical devices applications.

Capacitive Ceramic Pressure Sensor Market Analysis

- Capacitive ceramic pressure sensors are widely used due to their excellent mechanical strength, resistance to aggressive media, and wide pressure range compatibility.

- These sensors outperform silicon-based alternatives in harsh environments, including chemical processing, HVAC systems, and off-road vehicles, thanks to their non-corrosive, temperature-stable ceramic diaphragms.

- Demand is surging in automotive applications, including brake systems, engine control units (ECUs), and exhaust pressure monitoring, where precision and durability are critical.

- The medical industry is adopting capacitive ceramic sensors in ventilators, infusion pumps, and aesthesia machines, owing to their high stability and hygiene compliance.

- Innovation in compact sensor integration, digital signal processing, and IoT compatibility is expanding deployment across smart industrial systems and predictive maintenance platforms.

Report Scope and Capacitive Ceramic Pressure Sensor Market Segmentation

|

Attributes |

Capacitive Ceramic Pressure Sensor Market Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Capacitive Ceramic Pressure Sensor Market Trends

“Smart Miniaturization, Harsh Environment Adaptability, and Digital Integration”

- Miniaturization with Enhanced Performance: Manufacturers are designing compact capacitive ceramic sensors with improved accuracy and temperature compensation, enabling seamless use in wearable medical devices, miniature industrial tools, and space-constrained automotive systems.

- Growth in Harsh Environment Applications: The market is experiencing increased use of flush-mount and fully sealed ceramic sensors in corrosive or high-moisture environments, particularly in marine, chemical, and food processing industries.

- Digital Output and IoT Enablement: There’s a clear shift toward digital output formats, allowing for real-time diagnostics, predictive maintenance, and integration into IoT platforms for factory automation and smart infrastructure.

- Demand for Non-Oil-Filled Designs: Capacitive ceramic sensors, being media-isolated and non-oil-filled, are becoming preferred in medical, aerospace, and food-grade environments, where contamination risk must be minimized.

- Customization for End-Use Requirements: Market leaders are offering application-specific packaging, high-voltage versions, and low-pressure ceramic sensors for industries with unique sensing needs, supporting niche yet growing verticals like green hydrogen processing and off-grid energy systems.

Capacitive Ceramic Pressure Sensor Market Dynamics

Driver

“Widespread Demand for Rugged, Chemically Resistant, and Long-Life Pressure Sensing Solutions”

- Capacitive ceramic pressure sensors offer superior resistance to corrosion, shock, and thermal cycling, making them the top choice for aggressive media environments such as hydraulic fluid, chlorinated water, and fuel systems.

- Industries such as automotive, HVAC, and industrial automation are rapidly moving toward solid-state, maintenance-free sensors, fueling growth for capacitive ceramic types.

- With the rise of electric vehicles, these sensors are seeing increased demand for use in cooling systems, brake lines, and powertrain monitoring, where long-term stability is vital.

- The global push toward energy-efficient HVAC systems and smart medical infrastructure is driving installations of high-reliability pressure sensors that maintain calibration over years of service.

Restraint/Challenge

“Higher Cost and Complexity Compared to Conventional Silicon-Based Sensors”

- Capacitive ceramic pressure sensors involve more complex manufacturing processes and higher material costs, which can limit adoption in cost-sensitive markets or low-end consumer electronics.

- Their rigid structure and brittleness under improper installation or impact can cause premature failure if not integrated properly, especially in mobile or vibration-heavy environments.

- Design customization for non-standard form factors or proprietary connectors requires longer lead times and increases cost, deterring small-scale OEMs from opting for ceramic over traditional sensors.

- Competing technologies like MEMS-based silicon pressure sensors continue to improve in ruggedness and price performance, creating competitive pricing pressure in mid-range industrial applications.

Capacitive Ceramic Pressure Sensor Market Scope

The market is segmented on the type, End Use, Output Signal, Pressure Range and sales channel.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By End Use |

|

|

By Output Signal |

|

|

By Pressure Range |

|

Capacitive Ceramic Pressure Sensor Market Scope

The market is segmented based on type, end use, output signal, and pressure range, reflecting its versatile use across industries requiring rugged, accurate pressure monitoring.

• By Type

Includes Flush Mount, Threaded, and Compact sensors. Threaded sensors dominate in 2025 due to ease of installation in pipelines, tanks, and industrial machinery. Compact sensors are growing rapidly in medical and consumer devices for their miniaturized form factors.

• By End Use

Covers Automotive, Industrial, Medical, Aerospace & Defense, Consumer Electronics, HVAC, and Others. Automotive is the leading end-use segment in 2025, driven by stringent emissions regulations and vehicle safety standards. The medical and HVAC sectors are emerging as high-growth areas due to regulatory mandates and efficiency demands.

• By Output Signal

Divided into Analog, Digital, and Others. Analog output remains dominant due to cost-effectiveness and broad legacy system compatibility. However, digital output is growing fastest due to real-time diagnostics, IoT integration, and signal precision.

• By Pressure Range

Segmented into Low (<10 bar), Medium (10–100 bar), and High (>100 bar). The medium pressure segment leads in 2025 with extensive usage in automotive, hydraulic systems, and compressed air monitoring. High-pressure variants are favored in defense and deep well applications.

Capacitive Ceramic Pressure Sensor Market Regional Analysis

- North America leads in 2025, driven by strong adoption in automotive emissions control, industrial automation, and medical equipment manufacturing. The U.S. leads with automotive OEMs integrating ceramic sensors into EV battery packs and fuel systems.

- Europe holds a substantial market share, with countries like Germany, France, and Italy emphasizing eco-friendly HVAC, precision agriculture, and pharmaceutical-grade instrumentation, which require high-accuracy ceramic sensors.

- Asia-Pacific is the fastest-growing region due to surging demand in automotive manufacturing, electronics, and medical device production in China, India, Japan, and South Korea. Growth is further supported by government initiatives in smart factories and healthcare modernization.

- Middle East and Africa (MEA) is experiencing rising adoption in oil & gas monitoring systems, water desalination plants, and defense infrastructure, with the Gulf region investing in pressure sensing for hazardous and saline environments.

- South America, led by Brazil and Argentina, shows growing usage in industrial processing, mining operations, and transportation fleets, where ceramic pressure sensors are applied to improve durability and reduce service downtime.

United States

The U.S. remains a key hub for automotive, medical, and industrial sensor innovation, with ceramic sensors used in EV cooling, smart ventilators, and oil field automation. The country’s focus on semiconductor self-reliance also drives R&D in advanced ceramic sensor modules.

Germany

Germany is at the forefront of industrial sensor deployment, especially in green HVAC systems, factory automation, and biotech equipment. German OEMs value capacitive ceramic sensors for their long-term precision and resistance to aggressive cleaning agents.

China

China is rapidly scaling adoption in consumer electronics, air purifiers, and electric vehicles. Domestic sensor producers are increasing their focus on ceramic pressure sensing for medical devices and HVAC systems to reduce dependence on imports.

India

India’s sensor demand is growing in water resource monitoring, pharmaceutical production, and transportation logistics. Government programs supporting smart city and smart health infrastructure boost adoption of durable, non-silicon sensor types.

Brazil

Brazil is emerging as a regional consumer of ceramic sensors in agro-industrial systems, refrigeration, and public infrastructure. Rugged, non-oil-filled sensors are particularly useful in remote-area pumping systems and mining safety equipment.

Capacitive Ceramic Pressure Sensor Market Share

The Capacitive Ceramic Pressure Sensor industry is primarily led by well-established companies, including:

- BD|SENSORS GmbH (Germany)

- Keller AG für Druckmesstechnik (Switzerland)

- CeramTec GmbH (Germany)

- TE Connectivity (Switzerland)

- First Sensor AG (a TE Connectivity Company) (Germany)

- GE Measurement & Control (Baker Hughes) (U.S.)

- Sensata Technologies (U.S.)

- Honeywell International Inc. (U.S.)

- WIKA Group (Germany)

- Micro Sensor Co., Ltd. (China)

Latest Developments in Global Capacitive Ceramic Pressure Sensor Market

- In April 2025, BD|SENSORS GmbH launched a new ultra-compact threaded capacitive ceramic pressure sensor for high-pressure industrial cleaning systems, optimized for chemical resistance and rapid-response monitoring.

- In March 2025, CeramTec GmbH introduced an advanced multilayer ceramic diaphragm technology to extend sensor life in aggressive fluid media, targeting pharmaceutical and chemical manufacturing applications.

- In February 2025, TE Connectivity expanded its digital ceramic sensor range for automotive EV platforms, integrating SPI/I²C interfaces for real-time thermal and pressure monitoring in battery management systems.

- In January 2025, Sensata Technologies unveiled a new AI-enabled predictive pressure sensing module designed for HVAC systems, offering built-in analytics for air compressor fault detection.

- In December 2024, Keller AG announced a fully sealed capacitive ceramic pressure transmitter series with submersible capability, suitable for hydrostatic level sensing in water treatment and environmental monitoring.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Capacitive Ceramic Pressure Sensor Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Capacitive Ceramic Pressure Sensor Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Capacitive Ceramic Pressure Sensor Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.