Global Metal Forming Market

市场规模(十亿美元)

CAGR :

%

USD

247.65 Billion

USD

441.68 Billion

2023

2031

USD

247.65 Billion

USD

441.68 Billion

2023

2031

| 2024 –2031 | |

| USD 247.65 Billion | |

| USD 441.68 Billion | |

|

|

|

|

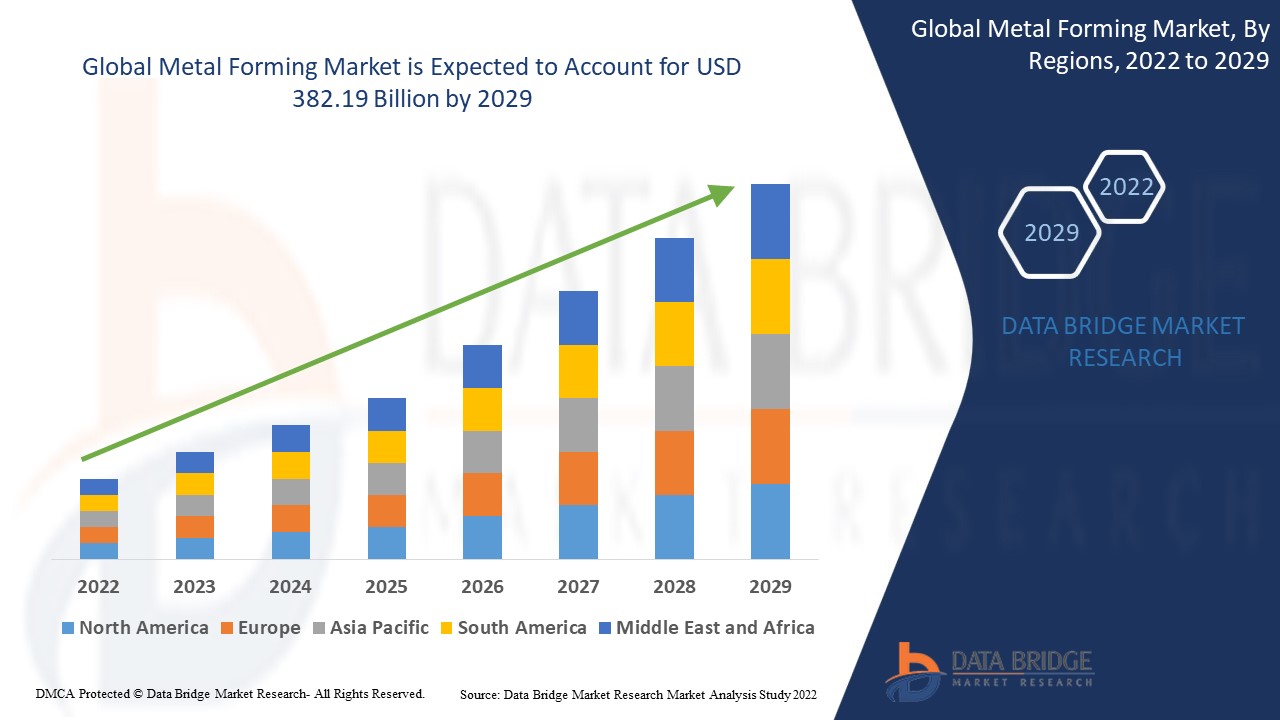

2023 年全球金属成型市场价值为 2476.5 亿美元,预计将以 7.50% 的复合年增长率增长,到 2031 年达到 4416.8 亿美元。

全球金属成型市场概况

金属成型是工业生产中的一个重要工艺,它用各种金属合金制作和生产高价值部件。持续研究生产技术对于了解金属的成型方式、减少缺陷和预测产品的最终性能至关重要。了解锻造、冲压和挤压等关键的金属成型方法对制造商和买家都至关重要。掌握这些技术有助于提高生产效率并确保最终部件满足特定要求。金属成型工艺的创新促进了金属成型市场的增长。据 AMPCO METAL 称,金属成型行业占工业化国家 GDP 的 15-20%,突显了其对经济的重大影响。

数据桥市场研究市场报告提供了最新发展、贸易法规、市场份额、基于细分和区域分析的市场趋势、市场参与者的影响、新兴收入领域机会分析、市场法规、战略市场增长分析、市场规模、类别市场增长、应用领域和主导地位、产品批准、产品发布、地理扩展和市场技术创新的详细信息。要获取有关市场的更多信息,请联系数据桥市场研究的专家分析师团队。我们的团队将帮助您做出明智的市场决策,以实现业务增长。

全球金属成型市场规模

|

全球金属成型市场报告指标 |

|

|

预测期 |

2024-2031 |

|

基准年 |

2023 |

|

历史年份 |

2022(可定制 2016-2021) |

|

測量單元 |

百万美元 |

|

数据指针 |

市场价值、增长率、市场细分、地理覆盖范围、市场参与者和市场情景、深入的专家分析、进出口分析、定价分析、生产消费分析和杵分析。 |

金属成型技术种类繁多,例如弯曲、拉伸、深拉、辊压成型、挤压、冲孔、压印、熨烫和液压成型,可帮助制造商提供所需的结果。随着金属成型在汽车、航空航天和消费电子等各个行业的应用不断扩大,金属成型市场的需求也不断增长。Databridge Market Research 深入全面分析了市场,并发现全球金属成型市场正以 7.50% 的复合年增长率增长。2023 年市场规模价值 2476.5 亿美元,预计到 2031 年将增长到 4416.8 亿美元。汽车和建筑行业的扩大刺激了对管道和管弯曲设备(如 CNC 制造机)的需求,这些设备可提供最大的效率和增强的流程透明度,直接使市场受益。

全球金属成型市场动态

全球金属成型市场的增长动力

创新成型技术推动市场增长

随着各行各业越来越重视创新设计和功能能力,对金属成型中复杂几何形状的需求正在推动市场增长。先进的成型技术对于适应这些复杂的形状、增强产品性能和促进汽车、航空航天和消费电子等领域的创造力至关重要。这种能力提高了材料效率并减轻了重量。计算机辅助设计 (CAD) 和精密工具等先进制造技术的集成有助于创建这些复杂的形状,满足市场对高质量和定制解决方案的需求。

金属的多种特性

金属的多样化特性对于加速金属成型市场的发展至关重要,尤其是在汽车领域。随着制造商越来越重视轻质、高强度的材料,对先进金属成型技术的需求也随之激增。随着行业向电动和混合动力汽车发展,这一工艺至关重要,需要独特的结构特性。铝和镁等材料的加入提高了燃油效率,有利于制造商满足汽车行业对休闲车的高需求。

可支配收入增加推动汽车定制化

由于可支配收入的增加,消费者对汽车定制的需求日益增长,这反过来又极大地推动了金属成型市场的发展。随着消费者越来越多地寻求个性化的汽车功能,制造商正在投资先进的金属成型技术来满足这些定制需求。这种向个性化汽车解决方案的转变刺激了金属成型行业的进步和增长。为了迎合更富裕的客户群,对精密工程和定制设计的需求凸显了金属成型在适应不断变化的市场偏好方面发挥的重要作用。因此,消费者财富和定制需求的交汇正在重塑行业格局。

金属成型市场的增长机会

由于出现了一些新兴机会,金属成型市场预计将大幅增长。NASA 和 ISRO 等组织在航空领域的创新迫切需要轻质、高强度的金属,为冲压和液压成型等先进成型技术创造了机会。例如,2022 年 4 月,NASA 发射了合金 GRX-810,这是一种耐高温氧化物弥散强化合金。它使用先进的 3D 打印技术实现均匀的氧化物弥散,增强了强度和灵活性,为航空航天和汽车行业提供了一条通往更轻、更高效零件的道路。这项创新扩大了对尖端成型技术和可持续制造实践的需求,以提高性能并降低成本。另一个机会是混合动力和电动汽车 (EV) 的激增需要智能制造技术,例如计算机辅助机器,使金属成型工艺更加高效和高产。此外,电动汽车的高产量预计将推动汽车行业的增长

金属成型市场规模增长挑战

金属成型行业面临熟练劳动力短缺的问题,这对该行业的发展和生产力构成了重大挑战。美国焊接学会估计,到 2024 年,该行业将短缺 40 万名焊工,而德国机械和设备工程行业报告称,截至 2022 年 6 月,近 80% 的公司面临严重或明显的熟练工人短缺问题。这种短缺可归因于多种因素,包括劳动力老龄化、年轻一代缺乏兴趣以及其他行业对熟练工人的竞争。然而,熟练劳动力短缺仍然是一个主要问题,因为它影响该行业的创新能力和增长前景。

金属成型市场规模增长限制

金属成型市场中工艺的复杂性受到严格的环境法规的显著影响,这些法规限制了行业的发展。这些法规要求遵守与排放、废物管理和资源利用相关的标准,迫使制造商投资于更清洁的技术和实践。虽然遵守这些法规对于最大限度地减少生态影响至关重要,但它往往需要大量成本和大量时间来实施,这可能会影响生产效率并增加运营费用。最终,虽然环境法规对于促进可持续发展至关重要,但它们带来的复杂性可能会阻碍金属成型市场的增长和效率。

全球金属成型市场范围和趋势

|

全球金属成型市场细分概述

|

|

|

技术 |

辊轧成型、拉伸成型、冲压、深拉、液压成型等 |

|

应用类型 |

白车身、底盘、封闭装置及其他 |

|

电动和混合动力汽车类型 |

燃料电池电动汽车 (FCEV)、插电式混合动力电动汽车 (PHEV) 和纯电动汽车 (BEV) |

|

内燃机车辆类型 |

乘用车、轻型商用车、卡车和公共汽车 |

|

成型类型 |

冷成型、热成型和温成型 |

|

材质类型 |

钢、铝、镁等 |

关键见解

- 液压成形是一种现代金属成形技术,利用高压液压油施加很大的力将金属成形为复杂的几何形状。与传统的冷成形方法相比,该技术具有显著的优势,可以减少所需的操作次数,从而生产出更轻、更坚固的部件,同时减少材料浪费。该技术正在不断发展,创新按其成熟度分类,未来趋势表明,人们将重点关注各行各业液压成形应用的进一步发展和研究。

- 电动汽车需求的不断增长反映了消费者偏好向更可持续的交通方式的重大转变。电动汽车的结构和电池系统需要先进的金属部件。插电式混合动力汽车销量的增长表明对轻质和高强度材料的需求不断增长,这对于提高汽车效率和性能至关重要。

- 冷成型是内燃机汽车最广泛使用的金属成型技术。它涉及在室温下成型部件,与热成型相比具有成本效益。冷成型因其总体成本低而成为全球原始设备制造商的首选

- 5052 铝合金是用于钣金制造的最常用合金,因为它具有出色的延展性和在成型过程中的抗开裂性,非常适合需要高可加工性的应用,例如海洋环境和汽车部件。虽然 6061 铝合金因其强度而成为 CNC 加工的首选,但 5052 的独特性能确保了其在钣金应用中的主导地位,对金属成型市场的整体铝部分产生了重大影响

- 2021 年美国乘用车销量将增至 1190 万辆,这对金属成型市场产生了积极影响,因为汽车产量的增加需要更多的金属部件。汽车制造业的激增推动了用于生产底盘、车身面板和发动机部件等零件的金属成型工艺的增长。

金属成型市场区域分析 – 市场趋势

|

金属成型市场区域概览 |

|

|

区域 |

国家 |

|

欧洲 |

德国、法国、英国、荷兰、瑞士、比利时、俄罗斯、意大利、西班牙、土耳其、欧洲其他地区 |

|

亚太地区 |

中国、日本、印度、韩国、新加坡、马来西亚、澳大利亚、泰国、印度尼西亚、菲律宾、亚太地区其他地区 |

|

北美 |

美国、加拿大和墨西哥 |

|

中东及非洲 |

沙特阿拉伯、阿联酋、南非、埃及、以色列、中东和非洲其他地区 |

|

南美洲 |

巴西、阿根廷和南美洲其他地区 |

关键见解

- 由于严格的环境法规和青睐可持续生产实践的消费者偏好的改变,北美正在引领向环保产品的重大转变。

- 北美的严格法规迫使制造商采取措施,尽量减少使用对健康和环境有害的挥发性有机化合物 (VOC)。

- 美国环境保护署 (EPA) 根据 40 CFR 59 执行严格的标准,以规范工业活动(包括金属成型)产生的挥发性有机化合物 (VOC) 排放。这些法规要求制造商采用更清洁的技术和工艺来遵守排放限制,从而影响金属成型市场,进而影响运营成本并推动创新走向更环保的做法。

- 北美在可持续实践创新方面处于领先地位,在响应环境要求和监管框架方面引领着全球趋势。

- 由于主要汽车制造公司以及豪华、紧凑型和中型汽车产量的增加,预计亚太地区汽车市场将大幅增长。

- 日本、韩国、中国和印度等国家凭借其强大的工业基础设施和熟练的劳动力在这一增长中发挥着至关重要的作用。

- 亚太地区轻型汽车产量创下新高,2023 年将达到 5180 万辆,这对金属成型市场产生了重大影响。这一增长主要归因于中国和日本的强劲制造业,这直接增加了对汽车生产中使用的金属部件的需求。

金属成型市场的领先企业

- 布莱伯里集团(英国)

- Formtek Molding Solutions(南非)

- Mestek Machinery(美国)

- 航空工业制造技术研究所(中国)

- VNT Automotive GmbH(奥地利)

- Westway Machinery(加拿大)

- 本特勒国际股份公司 (德国)

- AES Automotive Company Pvt. Ltd.(印度)

- 丰田纺织株式会社(日本)

- Samco 机械 (印度)

- 爱信精机株式会社(日本)

- Heck Industries(美国)

- 武汉化工舒勒印度私人有限公司(印度)

- 麦格纳国际公司(加拿大)

- 德雷克斯勒公司 (美国)

- Hirotec Corporation(日本)

- CIE 汽车 (西班牙)

最新动态

- 2024 年 2 月,Allied Nippon 推出了 EV+,这是专为电动汽车 (EV) 设计的专业刹车片系列。仅在英国就有超过一百万辆电动汽车,EV+ 通过新的摩擦复合材料和 BRAKEBOOST 即时摩擦层满足了电动汽车的独特需求,确保了更高的稳定性和安静的运行。此次发布彰显了 Allied Nippon 致力于满足日益增长的电动汽车售后产品需求的承诺。

- 2023 年 10 月,Brembo 在 AAPEX 上宣布了一项新的售后刹车片战略,推出了无铜 XTRA 系列。其中包括低金属和陶瓷 NAO 配方,旨在提高车辆安全性和环境可持续性。新刹车片是对 Brembo 现有 XTRA 系列的补充,为发烧友和高性能车辆量身定制的售后刹车片提供高性能摩擦材料。

- 2022 年 12 月,Torque Capital Group 收购了 MFC Netform,此举旨在增强 MFC Netform 的市场产品。此次收购旨在为公司注入新技术和能力,增强其竞争力和增长潜力。这项战略投资彰显了 Torque Capital Group 对创新和行业领导地位的承诺。

- 2020 年 4 月,Veoneer 与 ZF Friedrichshafen AG 达成协议,将 Veoneer 的美国制动控制业务转让给 ZF。这一战略举措旨在扩大 ZF Friedrichshafen AG 的全球市场份额,利用 Veoneer 在制动控制系统方面的专业知识来增强其在汽车行业的产品供应和地理覆盖范围。

Data Bridge Market Research 的生物仿制药市场报告将为您提供宝贵的见解,这些见解有助于您做出多项重要的业务决策。根据我们的报告和研究专业知识,您可以为您的业务制定切实可行的增长战略。

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。