Global Industrial Maintenance Services In Operational Improvement And Operational Maintenance Market

市场规模(十亿美元)

CAGR :

%

USD

51.77 Billion

USD

80.36 Billion

2022

2030

USD

51.77 Billion

USD

80.36 Billion

2022

2030

| 2023 –2030 | |

| USD 51.77 Billion | |

| USD 80.36 Billion | |

|

|

|

|

全球工業維護服務在營運改善和營運維護市場中的應用,按服務類型(工業運營維護、工業運營改進)、應用(監控和數據採集 (SCADA)、電動機和驅動器、閥門和執行器、分散式控制系統 (DCS)、人機界面 (HMI)、製造執行系統(MES)、安全系統等)、產業(汽車、金屬和採礦、食品和飲料、航空航太和國防、石油和天然氣、水和廢水、能源和電力、化學、製藥等)– 產業趨勢和預測到 2030 年。

工業維護服務在營運改善和營運維護市場的分析和規模

製造過程屬於高度複雜的過程,需要使用各種類型的機器。設施規模大幅擴張,機器種類多。此外,由於終端用戶需求不斷成長,各行各業的產能始終處於極限狀態。這些因素也使得設施的維護和檢查變得極為困難。此外,機器的複雜性往往需要高素質的專業人員,而公司員工往往缺乏這樣的人才。因此,需要提供工業維護服務的企業。公司只聘用經驗豐富、高素質且接受過維護專業訓練的人才。

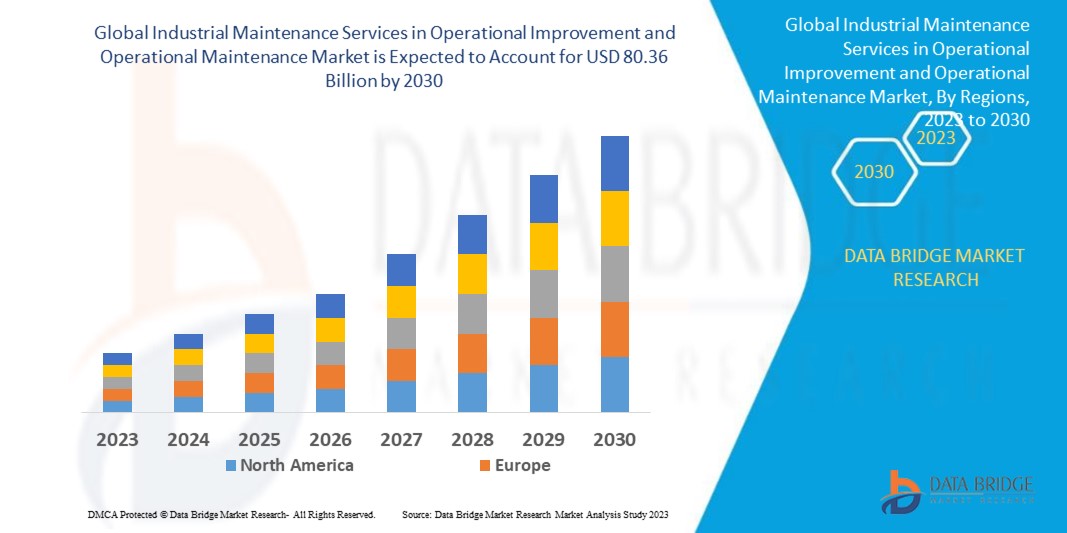

Data Bridge Market Research 分析認為,2022 年營運改善和營運維護市場中的工業維護服務價值為 517.7 億美元,到 2030 年將達到 803.6 億美元,在 2023 年至 2030 年的預測期內,複合年增長率為 5.65%。除了對市場價值、成長率、細分、地理覆蓋範圍和主要參與者等市場情景的洞察外,Data Bridge Market Research 策劃的市場報告還包括深入的專家分析、按地理位置代表的公司生產和產能、分銷商和合作夥伴的網絡佈局、詳細和更新的價格趨勢分析以及供應鏈和需求的缺口分析。

營運改善和營運維護市場範圍和細分中的工業維護服務

|

報告指標 |

細節 |

|

預測期 |

2023年至2030年 |

|

基準年 |

2022 |

|

歷史歲月 |

2021(可自訂為 2015 - 2020 年) |

|

定量單位 |

收入(十億美元)、銷售(單位)、定價(美元) |

|

涵蓋的領域 |

服務類型(工業運營維護、工業運營改進)、應用(監控和數據採集 (SCADA)、電動機和驅動器、閥門和執行器、分佈式控制系統 (DCS)、人機界面 (HMI)、製造執行系統 (MES)、安全系統、其他)、行業(汽車、金屬和採礦、食品和飲料、航空航天和國防、石油和天然氣、水和廢水、能源和電力、化學、製藥、其他) |

|

覆蓋國家 |

北美洲的美國、加拿大和墨西哥、德國、法國、英國、荷蘭、瑞士、比利時、俄羅斯、義大利、西班牙、土耳其、歐洲其他地區、中國、日本、印度、韓國、新加坡、馬來西亞、澳洲、泰國、印尼、菲律賓、亞太地區 (APAC) 的其他地區、沙烏地阿拉伯、阿聯酋、南非、埃及、以色列、中東和非洲 (MEA) 的其他地區、其他地區的歐洲地區 |

|

涵蓋的市場參與者 |

ABB(瑞士)、西門子(德國)、施耐德電機(法國)、霍尼韋爾國際公司(美國)、通用電氣(美國)、艾默生電氣公司(美國)、羅克韋爾自動化(美國)、江森自控(愛爾蘭)、SKF(瑞典)、三菱電機株式會社(日本)、橫河電機株式會社(日本)、丹納赫(美國)、AECOM(美國)、KBR公司(美國)、威立雅環境公司(法國)、Tetra Tech公司(美國)、約翰伍德集團(英國)、SNC-蘭萬靈集團(加拿大)、福陸公司(美國)、Jacobs公司(美國)、沃利(澳洲)、貝克特爾公司(美國)、博萊克威奇控股公司(美國)、世邦魏理仕(美國) |

|

市場機會 |

|

市場定義

營運維護和營運改善是工業維護服務的兩個主要組成部分。營運改善旨在透過流程最佳化、自動化和設備升級來提高整體效率和生產力。它旨在提高生產力、減少停機時間、降低成本並提升營運效率。相反,營運維護則包含常規和預防性維護程序,以確保設備高效運作、發現潛在問題並延長資產使用壽命。工業維護服務可協助企業實現生產目標、提高設備可靠性、減少停機時間並最大限度地利用資源,從而提高營運效率並節省成本。

工業維護服務在營運改善和營運維護市場動態

驅動程式

- 環境穩定推動市場成長

環境永續性是工業維護服務在營運改善和營運維護方面的關鍵驅動力。透過優化能源消耗,維護服務可協助企業減少碳足跡並減輕環境影響。維護服務能夠發現機會,最大限度地減少廢棄物產生,推廣回收和負責任的處置方式,並實施環保解決方案。隨著企業努力以更永續的方式運營,這與日益重視環境永續性和企業社會責任的趨勢相契合。透過將永續實踐融入維護運營,企業可以為更綠色的未來做出貢獻,滿足監管要求,提升企業聲譽,並吸引具有環保意識的利害關係人。

- 安全性的提高推動了市場

安全性的提升是工業維護服務在營運改善和營運維護方面的關鍵驅動力。透過定期檢查和預防性維護,這些服務有助於識別和糾正設備和系統中的潛在安全隱患。解決諸如線路故障、安全機制失靈或零件磨損等問題,可以降低工作場所發生事故和受傷的風險。維護服務也能確保遵守安全法規和業界標準,為員工創造更安全的工作環境。透過優先考慮安全,組織可以保護員工,最大限度地減少事故造成的停機時間,並建立安全意識文化,從而促進員工福祉和生產力。

機會

- 技術進步推動市場擴張

技術進步為工業維護服務在營運改善和營運維護方面創造了機會。這些服務利用先進的工具和技術,例如數據分析、物聯網 (IoT) 和預測性維護軟體,來提升其效率。透過收集和分析設備感測器的數據,維護服務可以識別模式、預測故障並主動安排維護活動。這使組織能夠做出明智的決策,優化資源配置並減少計劃外停機時間。採用這些技術可以提高效率、降低成本並改善整體資產性能,使組織能夠實現更高的生產力和可靠性,同時最大限度地延長其工業資產的使用壽命。

- 相關性增加激增的市場機會

可靠性的提升促進了工業維護服務在營運改善和營運維護領域的擴展。這些服務專注於確保工業資產和設備可靠運行,最大限度地減少意外故障和計劃外停機。透過定期檢查、預防性維護措施和及時維修,維護服務可以主動解決潛在問題,並使關鍵系統保持最佳狀態。透過維持設備的可靠性,組織可以降低代價高昂的營運中斷風險,最大限度地提高生產力並實現生產目標。更高的可靠性還能確保產品品質一致並按時交付,從而提升客戶滿意度,從而增強組織的聲譽和競爭力。

限制/挑戰

- 成本可能會成為市場的一個限制因素

成本是工業維護服務在營運改善和維護方面的主要限制因素。實施改進措施和定期維護活動通常需要在設備升級、自動化系統和熟練勞動力方面進行大量投資。這些費用可能會對企業的預算造成壓力,從而限制其提供這些服務的程度。預算限制可能會迫使企業優先考慮維護活動或推遲某些改進計劃,這可能會影響其營運的整體有效性和效率。在確保工業資產的可靠性和性能的同時,平衡成本效益解決方案的需求是工業維護服務面臨的關鍵挑戰。

- 缺乏技能和專業知識可能會阻礙市場成長

技能和專業知識是工業維護服務在營運改善和維護方面面臨的重大限制因素。成功執行改進計劃和複雜的維護任務通常需要專業知識和技能。然而,獲得合格的人員或外包服務可能頗具挑戰性,尤其是在偏遠地區或缺乏熟練技術人員的行業。熟練專業人員的短缺可能導致延誤、品質問題和成本增加。這要求組織投資培訓項目,吸引和留住人才,或探索外包或合作夥伴關係等替代方案,以克服這些與技能相關的限制因素,並確保有效實施改進和維護活動。

這份工業維護服務在營運改善和營運維護市場的應用報告,詳細介紹了最新發展動態、貿易法規、進出口分析、生產分析、價值鏈優化、市場份額、國內和本地市場參與者的影響,並分析了新興收入來源、市場法規變化、戰略市場增長分析、市場規模、品類市場增長、應用領域和擴展如需了解更多關於工業維護服務在營運改善和營運維護市場中應用的信息,請聯繫數據橋市場研究部門獲取分析師簡報,我們的團隊將幫助您做出明智的市場決策,實現市場成長。

原材料短缺和運輸延誤的影響和當前市場情勢

Data Bridge 市場研究提供高水準的市場分析,並結合原材料短缺和運輸延誤的影響和當前市場環境提供資訊。這可以評估策略可能性,制定有效的行動計劃,並協助企業做出重要決策。

除了標準報告外,我們還提供對採購層面的深入分析,包括預測運輸延遲、按地區劃分的經銷商映射、商品分析、生產分析、價格映射趨勢、採購、類別績效分析、供應鏈風險管理解決方案、高級基準測試以及其他採購和戰略支援服務。

經濟放緩對產品定價和供應的預期影響

當經濟活動放緩時,各行各業都會受到影響。 DBMR 提供的市場洞察報告和情報服務,充分考慮了經濟衰退對產品定價和可及性所造成的預測影響。借助這些,我們的客戶通常能夠領先競爭對手一步,預測銷售和收入,並估算損益支出。

最新動態

- 2020年,艾默生電氣公司推出了基於擴增實境 (AR) 技術的服務,提升了客戶支援。新的遠端協助服務功能有助於解決工業閥門問題。該公司因此改進了其工業維護市場的產品組合。

- 2019年,西門子開發了Mindsphere應用程序,旨在改善驅動系統的預測服務。這款新應用程式為低壓Simotics馬達和Sinamics驅動系統提供有效的服務和維護。該公司希望透過有效的維護解決方案來擴大客戶群並創造更多收入。

全球工業維護服務在營運改善和營運維護市場範圍

營運改善和營運維護市場中的工業維護服務根據服務類型、應用和產業進行細分。這些細分市場的成長將幫助您分析行業中成長緩慢的細分市場,並為用戶提供有價值的市場概覽和市場洞察,幫助他們做出策略決策,確定核心市場應用。

服務類型

- 工業運作維護

- 工業營運改進

應用

- 監控和數據採集(SCADA)

- 電動馬達和驅動器

- 閥門和執行器

- 分散式控制系統(DCS)

- 人機介面(HMI)

- 製造執行系統(MES)

- 安全系統

- 其他的

產業

- 汽車

- 金屬和採礦

- 食品和飲料

- 航空航太和國防

- 石油和天然氣

- 水和廢水

- 能源和電力

- 化學

- 製藥

- 其他的

營運改善和營運維護市場中的工業維護服務區域分析/洞察

對營運改進和營運維護市場中的工業維護服務進行了分析,並根據上述服務類型、應用和行業提供了市場規模洞察和趨勢。

營運改善和營運維護市場報告中工業維護服務涵蓋的國家包括北美的美國、加拿大和墨西哥,歐洲的德國、法國、英國、荷蘭、瑞士、比利時、俄羅斯、義大利、西班牙、土耳其,歐洲的其他地區,中國、日本、印度、韓國、新加坡、馬來西亞、澳洲、泰國、印尼、菲律賓,亞太地區(APAC)的其他地區,沙烏地阿拉伯、阿聯酋、南非的其他

中國作為不斷增長的製造業中心和生產基地,在營運改善和營運維護解決方案領域佔據了工業維護服務的最大市場份額,以支持工業化進程。德國佔據了最大的市場份額,因為其對預防性維護服務的需求有助於有效地實現生產目標。然而,由於工業自動化程度不斷提高以及熟練資源的匱乏,美國佔據了該解決方案的最大市場份額。

報告的國家部分還提供了各個市場的影響因素以及國內市場監管變化,這些變化會影響市場的當前和未來趨勢。下游和上游價值鏈分析、技術趨勢、波特五力模型分析以及案例研究等數據點是預測各國市場情景的一些指標。此外,在對國家/地區數據進行預測分析時,還考慮了全球品牌的存在和可用性,以及它們因本土和國內品牌的激烈競爭或稀缺而面臨的挑戰,國內關稅和貿易路線的影響。

營運改善和營運維護市場份額分析中的競爭格局和工業維護服務

工業維護服務在營運改善和營運維護市場的競爭格局提供了按競爭對手劃分的詳細資訊。詳細資訊包括公司概況、公司財務狀況、收入、市場潛力、研發投入、新市場計劃、全球佈局、生產基地和設施、生產能力、公司優勢和劣勢、產品發布、產品寬度和廣度以及應用主導地位。以上提供的數據僅與公司在營運改善和營運維護市場中對工業維護服務的關注度相關。

在營運改善和營運維護市場中,工業維護服務的一些主要參與者包括:

- ABB(瑞士)

- 西門子(德國)

- 施耐德電機(法國)

- 霍尼韋爾國際公司(美國)

- 通用電氣(美國)

- 艾默生電氣公司(美國)

- 羅克韋爾自動化(美國)

- 江森自控。 (愛爾蘭)

- SKF(瑞典)

- 三菱電機株式會社(日本)

- 橫河電機株式會社(日本)

- 丹納赫(美國)

- AECOM(美國)

- KBR公司(美國)

- 威立雅環境公司(法國)

- Tetra Tech, Inc.(美國)

- 約翰伍德集團有限公司(英國)

- SNC-蘭萬靈集團(加拿大)

- 福陸公司(美國)

- 雅各布斯(美國)

- 沃利(澳洲)

- 貝克特爾公司(美國)

- Black & Veatch控股公司(美國)

- 世邦魏理仕(美國)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

目录

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET

2.2.1 VENDOR POSITIONING GRID

2.2.2 TECHNOLOGY LIFE LINE CURVE

2.2.3 MARKET GUIDE

2.2.4 COMPANY POSITIONING GRID

2.2.5 COMAPANY MARKET SHARE ANALYSIS

2.2.6 MULTIVARIATE MODELLING

2.2.7 TOP TO BOTTOM ANALYSIS

2.2.8 STANDARDS OF MEASUREMENT

2.2.9 VENDOR SHARE ANALYSIS

2.2.10 DATA POINTS FROM KEY PRIMARY INTERVIEWS

2.2.11 DATA POINTS FROM KEY SECONDARY DATABASES

2.3 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET : RESEARCH SNAPSHOT

2.4 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 PORTER’S FIVE FORCES

5.2 REGULATORY STANDARDS

5.3 TECHNOLOGICAL TRENDS

5.4 VALUE CHAIN ANALYSIS

5.5 COMPANY COMPARITIVE ANALYSIS

5.6 CASE STUDY

6 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET , BY SERVICES TYPE

6.1 OVERVIEW

6.2 INDUSTRIAL OPERATIONAL MAINTENANCE

6.2.1 PREDICTIVE MAINTENANCE

6.2.2 SCHEDULED MAINTENANCE

6.2.3 MECHANICAL

6.2.3.1. GENERAL LUBRICATION MAINTENANCE

6.2.3.2. PRODUCT RECTIFICATION MAINTENANCE

6.2.3.3. OTHERS

6.3 INDUSTRIAL OPERATIONAL IMPROVEMENT

6.3.1 COMPLAINCES

6.3.2 SYSTEM CONFIGURATION

6.3.3 RETROFIT & REPAIR

6.3.4 INFRASTRUCTURE AUDIT

6.3.5 INSTALLATION AND CONSULTING

7 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY APPLICATION

7.1 OVERVIEW

7.2 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

7.3 ELECTRIC MOTORS & DRIVES

7.4 MOTIONS CONTROLS

7.5 VALVES & ACTUATORS

7.6 DISTRIBUTED CONTROL SYSTEM (DCS)

7.7 HUMAN-MACHINE INTERFACE (HMI)

7.8 MANUFACTURING EXECUTION SYSTEM (MES)

7.9 SAFETY SYSTEM

7.9.1 EMERGENCY SHUTDOWN SYSTEM (ESD)

7.9.2 HIGH-INTEGRITY PRESSURE PROTECTION SYSTEMS (HIPPS)

7.9.3 FIRE & GAS MONITORING & CONTROL

7.9.4 TURBOMACHINERY CONTROL (TMC)

7.1 INDUSTRIAL ROBOTS

7.11 OTHERS

8 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY INDUSTRY

8.1 OVERVIEW

8.2 INTRALOGISTICS

8.2.1 BY SERVICES

8.2.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.2.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.3 AUTOMOTIVE

8.3.1 BY SERVICES

8.3.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.3.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.4 METALS & MINING

8.4.1 BY SERVICES

8.4.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.4.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.5 FOOD & BEVERAGES

8.5.1 BY SERVICES

8.5.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.5.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.6 AEROSPACE & DEFENSE

8.6.1 BY SERVICES

8.6.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.6.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.7 OIL & GAS

8.7.1 BY SERVICES

8.7.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.7.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.8 WATER AND WASTEWATER

8.8.1 BY SERVICES

8.8.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.8.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.9 ENERGY & POWER

8.9.1 BY SERVICES

8.9.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.9.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.1 CHEMICAL

8.10.1 BY SERVICES

8.10.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.10.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.11 PHARMACEUTICALS

8.11.1 BY SERVICES

8.11.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.11.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.12 OTHERS

9 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY GEOGRAPHY

9.1 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

9.1.1 NORTH AMERICA

9.1.1.1. U.S.

9.1.1.2. CANADA

9.1.1.3. MEXICO

9.1.2 EUROPE

9.1.2.1. GERMANY

9.1.2.2. FRANCE

9.1.2.3. U.K.

9.1.2.4. ITALY

9.1.2.5. SPAIN

9.1.2.6. RUSSIA

9.1.2.7. TURKEY

9.1.2.8. BELGIUM

9.1.2.9. NETHERLANDS

9.1.2.10. SWITZERLAND

9.1.2.11. SWEDEN

9.1.2.12. DENMARK

9.1.2.13. POLAND

9.1.2.14. NORWAY

9.1.2.15. FINLAND

9.1.2.16. CZECH REPUBLIC

9.1.2.17. REST OF EUROPE

9.1.3 ASIA PACIFIC

9.1.3.1. JAPAN

9.1.3.2. CHINA

9.1.3.3. SOUTH KOREA

9.1.3.4. INDIA

9.1.3.5. AUSTRALIA AND NEW ZELAND

9.1.3.6. SINGAPORE

9.1.3.7. THAILAND

9.1.3.8. MALAYSIA

9.1.3.9. INDONESIA

9.1.3.10. PHILIPPINES

9.1.3.11. TAIWAN

9.1.3.12. VIETNAM

9.1.3.13. REST OF ASIA PACIFIC

9.1.4 SOUTH AMERICA

9.1.4.1. BRAZIL

9.1.4.2. ARGENTINA

9.1.4.3. REST OF SOUTH AMERICA

9.1.5 MIDDLE EAST AND AFRICA

9.1.5.1. SOUTH AFRICA

9.1.5.2. EGYPT

9.1.5.3. SAUDI ARABIA

9.1.5.4. U.A.E

9.1.5.5. ISRAEL

9.1.5.6. KUWAIT

9.1.5.7. QATAR

9.1.5.8. REST OF MIDDLE EAST AND AFRICA

9.1.6 KEY PRIMARY INSIGHTS: BY MAJOR COUNTRIES

10 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET,COMPANY LANDSCAPE

10.1 COMPANY SHARE ANALYSIS: GLOBAL

10.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

10.3 COMPANY SHARE ANALYSIS: EUROPE

10.4 COMPANY SHARE ANALYSIS: ASIA PACIFIC

10.5 MERGERS & ACQUISITIONS

10.6 NEW PRODUCT DEVELOPMENT AND APPROVALS

10.7 EXPANSIONS

10.8 REGULATORY CHANGES

10.9 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

11 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, SWOT & DBMR ANALYSIS

12 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, COMPANY PROFILE

12.1 SCHNEIDER ELECTRIC

12.1.1 COMPANY SNAPSHOT

12.1.2 REVENUE ANALYSIS

12.1.3 PRODUCT PORTFOLIO

12.1.4 RECENT DEVELOPMENTS

12.2 EMERSON ELECTRIC CO.

12.2.1 COMPANY SNAPSHOT

12.2.2 REVENUE ANALYSIS

12.2.3 PRODUCT PORTFOLIO

12.2.4 RECENT DEVELOPMENTS

12.3 ROCKWELL AUTOMATION, INC.

12.3.1 COMPANY SNAPSHOT

12.3.2 REVENUE ANALYSIS

12.3.3 PRODUCT PORTFOLIO

12.3.4 RECENT DEVELOPMENTS

12.4 SKF GROUP

12.4.1 COMPANY SNAPSHOT

12.4.2 REVENUE ANALYSIS

12.4.3 PRODUCT PORTFOLIO

12.4.4 RECENT DEVELOPMENTS

12.5 SIEMENS

12.5.1 COMPANY SNAPSHOT

12.5.2 REVENUE ANALYSIS

12.5.3 PRODUCT PORTFOLIO

12.5.4 RECENT DEVELOPMENTS

12.6 ADVANCED TECHNOLOGY SERVICES INC.

12.6.1 COMPANY SNAPSHOT

12.6.2 REVENUE ANALYSIS

12.6.3 PRODUCT PORTFOLIO

12.6.4 RECENT DEVELOPMENTS

12.7 SGS SA

12.7.1 COMPANY SNAPSHOT

12.7.2 REVENUE ANALYSIS

12.7.3 PRODUCT PORTFOLIO

12.7.4 RECENT DEVELOPMENTS

12.8 QUANT AB

12.8.1 COMPANY SNAPSHOT

12.8.2 REVENUE ANALYSIS

12.8.3 PRODUCT PORTFOLIO

12.8.4 RECENT DEVELOPMENTS

12.9 METSO

12.9.1 COMPANY SNAPSHOT

12.9.2 REVENUE ANALYSIS

12.9.3 PRODUCT PORTFOLIO

12.9.4 RECENT DEVELOPMENTS

12.1 ICONICS, INC.

12.10.1 COMPANY SNAPSHOT

12.10.2 REVENUE ANALYSIS

12.10.3 PRODUCT PORTFOLIO

12.10.4 RECENT DEVELOPMENTS

12.11 GENERAL ELECTRIC

12.11.1 COMPANY SNAPSHOT

12.11.2 REVENUE ANALYSIS

12.11.3 PRODUCT PORTFOLIO

12.11.4 RECENT DEVELOPMENTS

12.12 INTECH PROCESS AUTOMATION INC.

12.12.1 COMPANY SNAPSHOT

12.12.2 REVENUE ANALYSIS

12.12.3 PRODUCT PORTFOLIO

12.12.4 RECENT DEVELOPMENTS

12.13 DYNAMYSK AUTOMATION LTD.

12.13.1 COMPANY SNAPSHOT

12.13.2 REVENUE ANALYSIS

12.13.3 PRODUCT PORTFOLIO

12.13.4 RECENT DEVELOPMENTS

12.14 ABB

12.14.1 COMPANY SNAPSHOT

12.14.2 REVENUE ANALYSIS

12.14.3 PRODUCT PORTFOLIO

12.14.4 RECENT DEVELOPMENTS

12.15 ENDRESS +HAUSER GROUP SERVICES AG

12.15.1 COMPANY SNAPSHOT

12.15.2 REVENUE ANALYSIS

12.15.3 PRODUCT PORTFOLIO

12.15.4 RECENT DEVELOPMENTS

12.16 HONEYWELL INTERNATIONAL INC

12.16.1 COMPANY SNAPSHOT

12.16.2 REVENUE ANALYSIS

12.16.3 PRODUCT PORTFOLIO

12.16.4 RECENT DEVELOPMENTS

12.17 YASKAWA AMERICA, INC.

12.17.1 COMPANY SNAPSHOT

12.17.2 REVENUE ANALYSIS

12.17.3 PRODUCT PORTFOLIO

12.17.4 RECENT DEVELOPMENTS

12.18 ROHRER BETEILIGUNGS-UND VERWALTUNGS GMBH

12.18.1 COMPANY SNAPSHOT

12.18.2 REVENUE ANALYSIS

12.18.3 PRODUCT PORTFOLIO

12.18.4 RECENT DEVELOPMENTS

12.19 TIETOEVRY

12.19.1 COMPANY SNAPSHOT

12.19.2 REVENUE ANALYSIS

12.19.3 PRODUCT PORTFOLIO

12.19.4 RECENT DEVELOPMENTS

12.2 WUNDERLICH-MALEC ENGINEERING INC.

12.20.1 COMPANY SNAPSHOT

12.20.2 REVENUE ANALYSIS

12.20.3 PRODUCT PORTFOLIO

12.20.4 RECENT DEVELOPMENTS

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST

13 CONCLUSION

14 RELATED REPORTS

15 ABOUT DATA BRIDGE MARKET RESEARCH

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。