Global Composite Intermediate Bulk Containers Market

Tamaño del mercado en miles de millones de dólares

Tasa de crecimiento anual compuesta (CAGR) :

%

| 2024 –2031 | |

| USD 2.11 Billion | |

| USD 2.79 Billion | |

|

|

|

Global Composite Intermediate Bulk Containers Market, By Technology (Aseptic Technology and Non-Aseptic Technology), Capacity (180 to 250 gallons, 250 to 300 gallons, 300 to 350 gallons, and Above 350 gallons), End Use (Industrial Chemicals, Paints, Inks & Dyes, Food & Beverage, Building & Construction, and Pharmaceuticals) - Industry Trends and Forecast to 2031.

Composite Intermediate Bulk Containers Market Analysis and Size

The global composite intermediate bulk containers (IBCs) market is experiencing steady growth due to several factors. With increasing industrialization across various sectors such as chemicals, food and beverages, pharmaceuticals, and agriculture, the demand for efficient and durable packaging solutions such as composite IBCs is rising. These containers offer lightweight construction, corrosion resistance, and enhanced durability, making them preferred choices for bulk material handling and transportation. In addition, stringent regulations regarding the transportation and storage of hazardous materials have propelled the adoption of composite IBCs due to their compliance with safety standards.

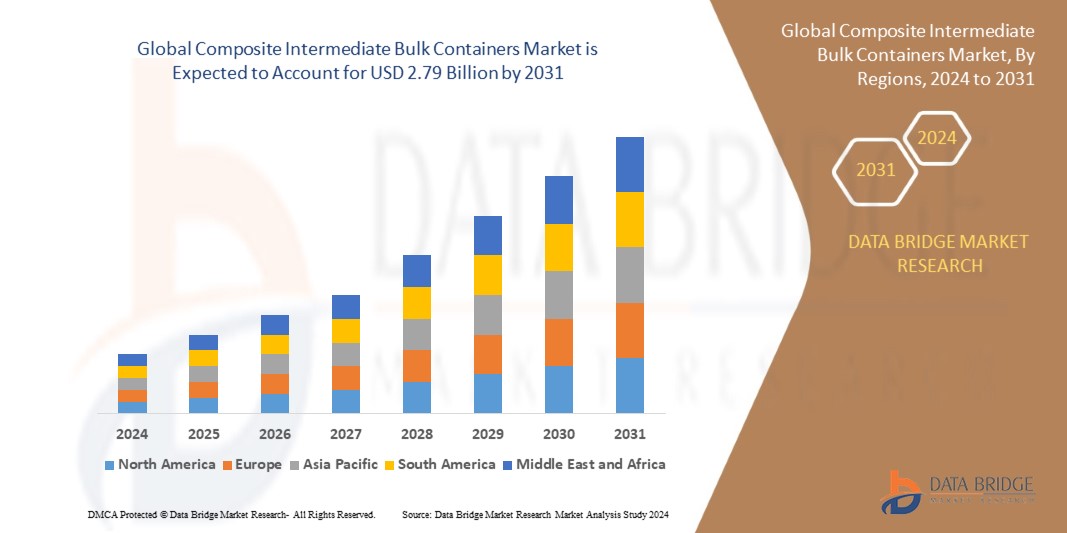

Data Bridge Market Research analyses that the global composite intermediate bulk containers market is expected to reach USD 2.79 billion by 2031, which is USD 2.11 billion in 2023, registering a CAGR of 3.6 % during the forecast period of 2024 to 2031.

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework.

Report Scope and Market Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2024 to 2031 |

|

Base Year |

2023 |

|

Historic Years |

2022(Customizable to 2016-2021) |

|

Quantitative Units |

Revenue in USD Billion, Volume in Units, Pricing in USD |

|

Segments Covered |

Technology (Aseptic Technology and Non-Aseptic Technology), Capacity (180 to 250 gallons, 250 to 300 gallons, 300 to 350 gallons, and Above 350 gallons), End Use (Industrial Chemicals, Paints, Inks & Dyes, Food & Beverage, Building & Construction, and Pharmaceuticals), |

|

Countries Covered |

U.S., Canada, Mexico, Germany, U.K., France, Spain, Belgium, Russia, Netherlands, Italy, Turkey, Switzerland, Sweden, Denmark, Norway, Finland, Rest of Europe, India, China, Japan, Australia, South Korea, Singapore, Thailand, Indonesia, Taiwan, Hong Kong, Malaysia, New Zealand, Philippines, Rest of Asia-Pacific, Brazil, Argentina Rest of South America, U.A.E., Saudi Arabia, South Africa, Egypt, Qatar, Kuwait, Bahrain, Oman, Israel, and Rest of Middle East and Africa |

|

Market Players Covered |

Grief Inc. (U.S.), Snyder Industries, Inc. (U.S.), Hoover Ferguson Group Inc. (U.S.), Mauser Group B.V. (Netherlands), WERIT Kunststoffwerke W. Schneider GmbH & Co. KG (Germany), Composite Containers LLC (U.S.), Pacific Container Systems (U.S.), Pyramid IBC Containers (India), and Time Technolplast Ltd. (India) |

|

Market Opportunities |

|

Market Definition

Composite intermediate bulk containers (IBCs) are storage vessels that are used for transporting and storing liquids and bulk materials. The combination materials such as plastic, metal, and composite materials are used in the manufacturing of these containers for additional strength, durability, and chemical resistance. These containers typically feature a rigid inner structure surrounded by a protective outer layer, offering both structural integrity and environmental protection. Composite IBCs are commonly used in industries such as chemicals, pharmaceuticals, and food processing for their ability to contain and transport a wide range of substances safely.

Composite Intermediate Bulk Containers Market Dynamics

This section deals with understanding the market drivers, advantages, opportunities, restraints, and challenges. All of these are discussed in detail below:

Drivers

- Increasing Demand for Lightweight and Durable Packaging Solutions

The rising demand for lightweight yet robust packaging solutions across various industries such as chemicals, food and beverages, and pharmaceuticals is driving the global composite IBC market. Compared to traditional metal or plastic containers, composite IBCs offer a combination of strength, durability, and weight reduction. This demand is further fueled by the need for efficient logistics and transportation solutions that minimize costs and improve handling efficiency.

- Successful Implementation of Standards for Hazardous Material Handling:

Regulatory requirements regarding the safe handling and transportation of hazardous materials are increasing the adoption of composite IBCs. These containers are engineered to meet stringent safety standards, offering leak-proof and corrosion-resistant properties that ensure the integrity of the transported goods. As governments worldwide impose stricter regulations on storing and transporting hazardous substances, the demand for compliant packaging solutions like composite IBCs continues to grow.

Opportunities

- Expansion of Industrial Manufacturing and Chemical Industries

The ongoing expansion of industrial manufacturing activities, particularly in emerging economies, presents a significant opportunity for the global composite IBC market. As industries such as chemicals, petrochemicals, and pharmaceuticals witness rapid growth, there is an escalating demand for reliable and efficient bulk packaging solutions. Composite IBCs offer a viable option due to their durability, corrosion resistance, and compatibility with a wide range of substances, positioning them as preferred choices for bulk material handling.

Restraints/Challenges

- High Initial Investment and Cost Concerns:

Composite IBCs offer long-term cost savings through enhanced durability and reduced maintenance, the upfront capital expenditure may deter some potential buyers, particularly small and medium-sized enterprises. Manufacturers need to address this challenge by emphasizing the long-term benefits and return on investment associated with composite IBCs to mitigate cost concerns among consumers.

- Limited Awareness and Adoption in Certain Regions:

Despite their numerous advantages, composite IBCs still face limited awareness and adoption in certain geographic regions, especially in developing economies. This lack of familiarity may be attributed to a preference for traditional packaging materials or a lack of understanding regarding the benefits of composite IBCs which inturn restraint the market growth.

This composite intermediate bulk containers market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the global composite intermediate bulk containers market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Recent Developments

- In October 2023, CDF Corp launched a new Form-Fit IBC liner manufacturing line in Germany in collaboration with J Natzan Kunststoffverarbeitung GmbH & Co KG. The initiative, operational by the end of 2023, marks their second European expansion since 2013. The Lienen facility specializes in producing liners for liquid to highly viscous products, offering environmentally responsible bulk packaging solutions. This move aligns with market trends towards sustainable packaging, reflecting the growing importance of environmental stewardship in the industry

- In September 2023, Greif, a global leader in industrial packaging, opened a new IBC manufacturing facility in Dilovasi, Turkey, on September 27, 2023. Spanning 13,000 square meters, it offers high-quality packaging solutions for food, chemical, and lubricant industries. The expansion aims to strengthen global presence, provide exceptional customer service, and foster partnerships for sustainable solutions. Greif's portfolio includes innovative products like GCUBE Shield and GCUBE Elektron, meeting specific customer requirements with customized valves and robust cages.

Composite Intermediate Bulk Containers Market Scope

The global composite intermediate bulk containers market is segmented on the basis of on material type, end use, technology, and capacity. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Technology

- Aseptic Technology

- Non-Aseptic Technology

Capacity

- 180 to 250 gallons

- 250 to 300 gallons

- 300 to 350 gallons

- Above 350 gallons

End Use

- Industrial Chemicals

- Paints

- Inks & Dyes

- Food & Beverage

- Building & Construction

- Pharmaceuticals

- Others

Composite Intermediate Bulk Containers Market Regional Analysis/Insights

The market is analyzed and market size insights and trends are provided on basis of on material type, end use, technology, and capacity.

The countries covered in the composite intermediate bulk containers market report are (U.S.), Canada, Mexico, Germany, U.K., France, Spain, Belgium, Russia, Netherlands, Italy, Turkey, Switzerland, Sweden, Denmark, Norway, Finland, Rest of Europe, India, China, Japan, Australia, South Korea, Singapore, Thailand, Indonesia, Taiwan, Hong Kong, Malaysia, New Zealand, Philippines, Rest of Asia-Pacific, Brazil, Argentina Rest of South America, U.A.E., Saudi Arabia, South Africa, Egypt, Qatar, Kuwait, Bahrain, Oman, Israel, and Rest of Middle East and Africa.

Europe region is dominating the growing the composite intermediate bulk containers market as the European manufacturers produce high-quality composite IBCs known for their durability and reliability, meeting the demanding requirements of various industries worldwide. In addition, Asia-Pacific is experiencing rapid growth in the global composite intermediate bulk containers (IBCs) market due to expanding industrial activities and increasing trade volumes in the region.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Technological Advancements or Research and Development in Composite Intermediate Bulk Containers Products

The composite intermediate bulk containers also provides you with detailed market analysis for every country growth in expenditure for capital equipment, installed base of different kind of products for global composite intermediate bulk containers market, impact of technology using life line curves and changes in regulatory scenarios and their impact on the market.

Competitive Landscape and Global Composite Intermediate Bulk Containers Market Share Analysis

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies focus related to the market.

Some of the major players operating in the market are:

- Grief Inc. (U.S.)

- Snyder Industries, Inc. (U.S.)

- Hoover Ferguson Group Inc. (U.S.)

- Mauser Group B.V. (Netherlands)

- WERIT Kunststoffwerke W. Schneider GmbH & Co. KG (Germany)

- Composite Containers LLC (U.S.)

- Pacific Container Systems (U.S.)

- Pyramid IBC Containers (India)

- Time Technolplast Ltd. (India)

SKU-

Obtenga acceso en línea al informe sobre la primera nube de inteligencia de mercado del mundo

- Panel de análisis de datos interactivo

- Panel de análisis de empresas para oportunidades con alto potencial de crecimiento

- Acceso de analista de investigación para personalización y consultas

- Análisis de la competencia con panel interactivo

- Últimas noticias, actualizaciones y análisis de tendencias

- Aproveche el poder del análisis de referencia para un seguimiento integral de la competencia

Metodología de investigación

La recopilación de datos y el análisis del año base se realizan utilizando módulos de recopilación de datos con muestras de gran tamaño. La etapa incluye la obtención de información de mercado o datos relacionados a través de varias fuentes y estrategias. Incluye el examen y la planificación de todos los datos adquiridos del pasado con antelación. Asimismo, abarca el examen de las inconsistencias de información observadas en diferentes fuentes de información. Los datos de mercado se analizan y estiman utilizando modelos estadísticos y coherentes de mercado. Además, el análisis de la participación de mercado y el análisis de tendencias clave son los principales factores de éxito en el informe de mercado. Para obtener más información, solicite una llamada de un analista o envíe su consulta.

La metodología de investigación clave utilizada por el equipo de investigación de DBMR es la triangulación de datos, que implica la extracción de datos, el análisis del impacto de las variables de datos en el mercado y la validación primaria (experto en la industria). Los modelos de datos incluyen cuadrícula de posicionamiento de proveedores, análisis de línea de tiempo de mercado, descripción general y guía del mercado, cuadrícula de posicionamiento de la empresa, análisis de patentes, análisis de precios, análisis de participación de mercado de la empresa, estándares de medición, análisis global versus regional y de participación de proveedores. Para obtener más información sobre la metodología de investigación, envíe una consulta para hablar con nuestros expertos de la industria.

Personalización disponible

Data Bridge Market Research es líder en investigación formativa avanzada. Nos enorgullecemos de brindar servicios a nuestros clientes existentes y nuevos con datos y análisis que coinciden y se adaptan a sus objetivos. El informe se puede personalizar para incluir análisis de tendencias de precios de marcas objetivo, comprensión del mercado de países adicionales (solicite la lista de países), datos de resultados de ensayos clínicos, revisión de literatura, análisis de mercado renovado y base de productos. El análisis de mercado de competidores objetivo se puede analizar desde análisis basados en tecnología hasta estrategias de cartera de mercado. Podemos agregar tantos competidores sobre los que necesite datos en el formato y estilo de datos que esté buscando. Nuestro equipo de analistas también puede proporcionarle datos en archivos de Excel sin procesar, tablas dinámicas (libro de datos) o puede ayudarlo a crear presentaciones a partir de los conjuntos de datos disponibles en el informe.