Global 3d Machine Vision Market

Market Size in USD Billion

CAGR :

%

USD

7.32 Billion

USD

19.21 Billion

2024

2032

USD

7.32 Billion

USD

19.21 Billion

2024

2032

| 2025 –2032 | |

| USD 7.32 Billion | |

| USD 19.21 Billion | |

|

|

|

|

3-Dimesional (3D) Machine Vision Market Size

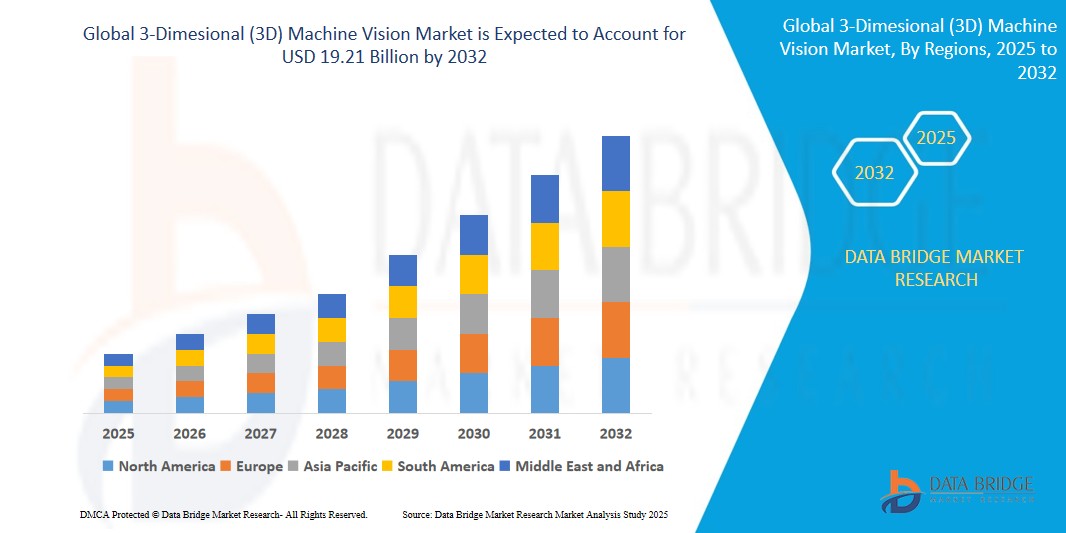

- The Global 3-Dimesional (3D) Machine Vision Market size was valued at USD 7.32 billion in 2024 and is expected to reach USD 19.21 billion by 2032, at a CAGR of 12.8% during the forecast period

- This growth is driven by rising demand for industrial automation services and awareness of consumers regarding product quality.

3-Dimesional (3D) Machine Vision Market Analysis

- Machine vision is a technology that is used to deliver imaging-based automatic analysis. 3D machine vision technology is used for inspection of various industrial applications such as process control, robot guidance, and automatic inspection. 3D machine vision technology comprises of hardware and software products, actions, technologies and integrated systems. 3D machine vision technology produces a point cloud (three dimensional coordinates) output as it deals with all the three axes (X, Y, and Z).

- Rising globalization and growth in the demand for this technology by defence, automotive, healthcare, semiconductors, consumer electronics and logistics industries will emerge as the major 3-dimesional (3D) machine vision market growth driving factor.

- Asia-Pacific is expected to be the dominating and fastest growing region in the 3-Dimesional (3D) Machine Vision Market during the forecast period due to rapid urbanization, increasing population, and a growing need for smart transportation networks.

- The hardware segment is anticipated to hold the largest market share in the 3D machine vision market, driven by the increasing demand for advanced imaging and automation systems in industries such as manufacturing and automotive. The integration of high-performance cameras, sensors, and lighting solutions in 3D machine vision systems is enhancing precision in quality assurance, inspection, and measurement processes, making it a critical component in automation.

Report Scope and 3-Dimesional (3D) Machine Vision Market Segmentation

|

Attributes |

3-Dimesional (3D) Machine Vision Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

3-Dimesional (3D) Machine Vision Market Trends

“Increasing Demand for Industrial Automation Solutions”

- The growing adoption of automation in industries such as automotive, electronics, and logistics is significantly driving the deployment of 3D machine vision systems. These systems enhance efficiency, reduce human error, and ensure consistent quality in manufacturing operations.

- With global manufacturers focusing on smart factories and Industry 4.0 transformation, the need for accurate and real-time visual inspection has increased substantially.

For instance,

- In November 2023, Siemens Digital Industries highlighted in its Industry 4.0 report that over 70% of European manufacturers were actively integrating 3D machine vision for quality inspection and robotic guidance in production lines.

3-Dimesional (3D) Machine Vision Market Dynamics

Driver

“Advancements in Vision-Guided Robotics”

- The rising integration of 3D machine vision with robotics has expanded the scope of automated material handling, inspection, and assembly operations. These technologies are becoming essential in sectors requiring high precision and flexibility.

- Improved hardware performance, along with deep learning-based image processing, is making vision-guided robots smarter and more adaptive.

For instance,

- In January 2024, Cognex Corporation announced the launch of its enhanced In-Sight 3D-L4000 vision system, enabling more accurate robotic alignment in complex industrial environments.

Opportunity

“Rising Adoption in the Healthcare and Pharmaceutical Sectors”

- The demand for 3D machine vision is rising in healthcare for applications such as surgical robotics, drug inspection, and diagnostic imaging.

- Increased focus on precision, hygiene, and regulatory compliance makes vision systems ideal for critical operations.

For instance,

- In February 2024, LMI Technologies partnered with a European medical device firm to develop 3D vision solutions for inspecting orthopedic implants, showcasing strong expansion into the medical sector.

Restraint/Challenge

“Lack of Standardization and Skilled Workforce”

- A key challenge in the widespread adoption of 3D machine vision is the absence of industry-wide standardization and compatibility across systems from different vendors.

- Further, there is a notable shortage of skilled personnel capable of deploying and maintaining these advanced systems, especially in developing regions.

For instance,

- In October 2023, the World Economic Forum reported that over 50% of industrial automation roles globally would require substantial reskilling by 2026, indicating a growing talent gap affecting adoption rates of 3D vision technologies.

3-Dimesional (3D) Machine Vision Market Scope

The 3-dimesional (3D) machine vision market is segmented on the basis of offering, vertical, product and application.

|

Segmentation |

Sub-Segmentation |

|

By Offering |

|

|

By Vertical |

|

|

By Product |

|

|

By Application

|

|

In 2025, Hardware Segment is Expected to Dominate the 3D Machine Vision Market

The hardware segment is anticipated to hold the largest market share in the 3D machine vision market, driven by the increasing demand for advanced imaging and automation systems in industries such as manufacturing and automotive. The integration of high-performance cameras, sensors, and lighting solutions in 3D machine vision systems is enhancing precision in quality assurance, inspection, and measurement processes, making it a critical component in automation.

In 2025, Industrial is Expected to Dominate the 3D Machine Vision Market in Vertical segment

The industrial vertical is projected to dominate the 3D machine vision market due to the growing adoption of automation technologies in manufacturing processes. Industries like automotive, electronics, and food & beverage are increasingly relying on 3D machine vision systems for tasks such as quality inspection, assembly, and packaging, driving the demand for machine vision solutions tailored to industrial needs.

3-Dimesional (3D) Machine Vision Market Regional Analysis

“North America Holds the Largest Share and Projected to Register the Highest CAGR in the 3-Dimesional (3D) Machine Vision Market”

- The Asia-Pacific region dominates the Automated Passenger Counting and Information System market, driven by rapid urbanization, increasing population, and a growing need for smart transportation networks.

- Countries like China and India are witnessing significant demand for these systems due to their expanding public transit networks and efforts to modernize infrastructure.

- Increased adoption of advanced technologies such as infrared and time-of-flight sensors is further fueling the growth of the market in this region.

- In addition, the rise in the need for secure, reliable, and timely transportation services among large populations contributes to the region’s dominance in the market.

3-Dimesional (3D) Machine Vision Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- OMRON Corporation(Japan)

- Cognex Corporation(United States)

- Basler AG(Germany)

- Keyence Corporation(Japan)

- NATIONAL INSTRUMENTS CORP(United States)

- TKH GROUP(Netherlands)

- ISRA VISION AG (Germany)

- STEMMER IMAGING AG(Germany)

- Intel Corporation(United States)

- Sick AG (Germany)

- MVTEC SOFTWARE GMBH(Germany)

- Tordivel AS(Norway)

- LMI TECHNOLOGIES INC.(Canada)

- Robotic Vision Technologies, Inc.(United States)

- Sony Corporation(Japan)

- Coherent, Inc. (United States)

- Hermary(Canada)

- Baumer(Switzerland)

- Texas Instruments Incorporated(United States)

Latest Developments in Global 3-Dimesional (3D) Machine Vision Market

- In April 2025, Cognex Corporation launched its latest In-Sight SnAPP vision sensor series, engineered to deliver compact, high-speed 3D inspection capabilities. This sensor is equipped with advanced edge-learning technology and an integrated smart camera, enabling real-time quality inspection, object positioning, and defect detection across fast-paced production environments such as electronics and consumer goods, without requiring complex setup or coding.

- In March 2025, LMI Technologies Inc. introduced the Gocator 2600 Series, an advanced line of 3D smart sensors offering ultra-high 9-megapixel resolution and 5-GigE interface. Tailored for precision manufacturing sectors like battery and electronics production, these sensors facilitate detailed 3D shape and volume analysis at high speeds, ensuring robust performance even under demanding industrial conditions.

- In February 2025, Basler AG revealed its new range of 3D Time-of-Flight (ToF) cameras, integrated with NVIDIA Jetson platforms for real-time processing efficiency. These cameras enhance depth sensing and speed in applications such as warehouse automation, logistics, and robotics. The seamless combination of high-performance hardware and intelligent processing significantly reduces latency and simplifies deployment.

- In January 2025, ISRA VISION AG, a company under the Atlas Copco Group, announced the rollout of its 3D Multi-View Inspection System designed for advanced surface analysis in automotive and aerospace manufacturing. This AI-driven system leverages multiple stereo imaging setups to accurately detect structural imperfections like gaps, deformations, and surface inconsistencies, increasing operational efficiency and reducing reliance on manual inspections.

- In November 2024, Keyence Corporation launched the IV3 Series, a 3D vision inspection system enhanced with deep learning capabilities. This solution supports automatic defect detection with minimal user configuration and eliminates the need for external lighting setups. Its simplified integration and intelligent analysis make it an ideal solution for SMEs aiming to automate visual quality control processes effectively and affordably.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global 3d Machine Vision Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global 3d Machine Vision Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global 3d Machine Vision Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.