The Russia refractories market is witnessing a growing demand due to the modernization and expansion of the manufacturing sector. Refractories play a critical role in industries such as steel, cement, glass, and non-ferrous metals by providing heat resistance and durability to withstand high temperatures and harsh conditions. With ongoing industrial development and infrastructure projects, the demand for refractories in Russia is increasing. Additionally, the emphasis on energy efficiency and environmental sustainability further drives the market as refractories contribute to reducing energy consumption and emissions in manufacturing processes. The market is expected to continue growing as industries seek advanced refractory solutions to enhance productivity and operational efficiency.

Access Full Report: https://www.databridgemarketresearch.com/reports/russia-refractories-market

Data Bridge Market Research analyses that the Russia Refractories Market value was USD 595.85 million in 2021 and expected to reach USD 815.46 million in 2029 with the CAGR of 4% in the forecast period of 2022 to 2029. The rise in infrastructure development in emerging countries serves as a driver for the Russia refractories market. Compliance with regulatory requirements for workplace safety, fire resistance, and environmental protection creates a demand for high-quality refractory materials in Russia. Industries seek refractories that meet these standards, driving market growth and the adoption of reliable and compliant refractory solutions.

Key Findings of the Study

Energy efficiency and environmental sustainability expected to drive the market's growth rate

The driver of the Russia refractories market is the emphasis on energy efficiency and environmental sustainability in manufacturing processes. With a focus on reducing energy consumption and emissions, industries are increasingly adopting refractories that offer superior thermal insulation properties and minimize heat loss. These energy-efficient refractories contribute to cost savings, improved operational efficiency, and reduced environmental impact. As a result, there is a growing demand for refractories that align with the goals of energy efficiency and environmental sustainability in Russia's manufacturing sector. .

Report Scope and Market Segmentation

|

Report Metric

|

Details

|

|

Forecast Period

|

2022 to 2029

|

|

Base Year

|

2021

|

|

Historic Years

|

2020 (Customizable to 2014-2019)

|

|

Quantitative Units

|

Revenue in USD Million, Volumes in Units, Pricing in USD

|

|

Segments Covered

|

Product Type (Non-Clay, Clay), Alkalinity (Acidic and Neutral Refractories, Basic Refractories), Manufacturing Process (Dry Press Process, Fused Cast, Hand Molded, Formed, Unformed), Fusion Temperature (Normal Refractory (1580-1780 0C), High Refractory (1780-2000 0C), Super Refractory (>2000 0C)), Form (Shaped, Unshaped) End User (Iron and Steel, Cement and Lime, Non-Ferrous Metal, Glass, Energy and Chemicals, Others)

|

|

Market Players Covered

|

RHI Magnesita (Austria), Vesuvias (U.S.), Imerys (France), Saint Gobain S.A. (France), Ruitai Materials Technology Co., Ltd. (China), Harbison Walker International (U.S.), Coorstek, Inc. (U.S.), IFGL Refractories Ltd. (India), Refratechnic Cement GmbH (Germany), HarbisonWalker International (U.S.)

|

|

Data Points Covered in the Report

|

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand..

|

Segment Analysis:

The refractories market is segmented on the basis of product type, alkalinity, manufacturing process, fusion temperature, form, and end user.

- On the basis of product type, the refractories market is segmented into non-clay, clay. The clay segment is estimated to dominate the product type segment with 62.3% market shares owing to its abundance in the region, cost-effectiveness, and excellent thermal insulation properties, making it a preferred choice for various industrial applications.

- On the basis of alkalinity, the refractories market is segmented into acidic and neutral refractories, and basic refractories. Acidic and neutral refractories market is projected to dominate market with 72.3% shares acidic and neutral exhibit excellent resistance to alkaline environments and high temperatures, making them suitable for applications in industries like steelmaking, where alkaline conditions are prevalent.

- On the basis of manufacturing process, the refractories market is segmented into dry press process, fused cast, hand molded, formed, unformed. The dry press process segment dominate the manufacturing process category due to manufacturing process offers high efficiency, precise shaping, and consistent quality, making it suitable for producing refractory components for refrigeration applications.

- On the basis of fusion temperature, the refractories market is segmented into normal refractory (1580-1780 0c), high refractory (1780-2000 0c), super refractory (>2000 0c). Normal Refractory (1580-1780 °C) market is estimated to dominate market with 54.0% shares .this is because high refractories possess superior heat resistance, making them suitable for various applications in industries such as steel, glass, and cement, which require materials capable of withstanding extremely high temperatures.

- On the basis of form, the refractories market is segmented into shaped, unshaped. The shaped segment is dominating the form category in Russia refractories market because it offers better dimensional accuracy and structural integrity, and suitable for applications that require precise shapes and configurations, such as lining in furnaces and kilns.

In 2022 the shaped category is dominating the form segment in Russia refractories market

In 2022, the shaped category is dominating the form segment in Russia refractories market due to shaped refractories, with their ability to be molded into specific shapes and configurations, provide better dimensional accuracy and structural integrity. This makes them ideal for applications like lining furnaces and kilns, where precise shapes and configurations are necessary for optimal performance and longevity.

- On the basis of end user, the refractories market is segmented into iron and steel, cement and lime, non-ferrous metal, glass, energy and chemicals, others. The iron and steel segment is estimated to dominate the end user segment with a CAGR 3.1% due to extensive use of refractory materials in the production processes of iron and steel, which require high heat resistance and durability, during the forecast period of 2022-2029

In 2022 iron and steel category is dominating the end user segment in Russia refractories market

In 2022 iron and steel category is dominating the end user segment in Russia refractories market with the market share of 85.3% owing to the extensively utilizes refractory materials in their production processes due to the high temperatures involved. Refractories provide excellent heat resistance and durability, enabling them to withstand extreme conditions of steelmaking, such as high temperatures, chemical reactions, and mechanical stress.

Major Players

Data Bridge Market Research recognizes the following companies as the major Russia refractories market players in russia refractories market RHI Magnesita (Austria), Vesuvias (U.S.), Imerys (France), Saint Gobain S.A. (France), Ruitai Materials Technology Co., Ltd. (China), Harbison Walker International (U.S.), Coorstek, Inc. (U.S.), IFGL Refractories Ltd. (India),

Market Development

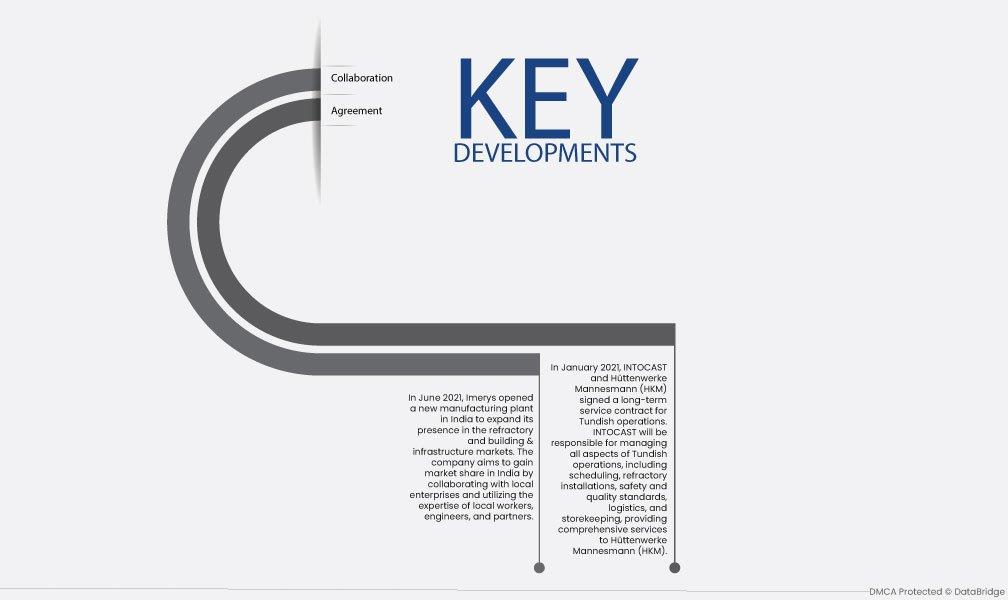

- In June 2021, Imerys opened a new manufacturing plant in India to expand its presence in the refractory and building & infrastructure markets. The company aims to gain market share in India by collaborating with local enterprises and utilizing the expertise of local workers, engineers, and partners.

- In January 2021, INTOCAST and Hüttenwerke Mannesmann (HKM) signed a long-term service contract for Tundish operations. INTOCAST will be responsible for managing all aspects of Tundish operations, including scheduling, refractory installations, safety and quality standards, logistics, and storekeeping, providing comprehensive services to Hüttenwerke Mannesmann (HKM).

For more detailed information about the Russia refractories market report, click here – https://www.databridgemarketresearch.com/reports/russia-refractories-market